Timm's BMW E31, E32, E36 and E38 - Making Error-

Free LED Licence-Plate Lights

A problem that I tried too hard to fix - and then found it was a problem that was already solved a while ago

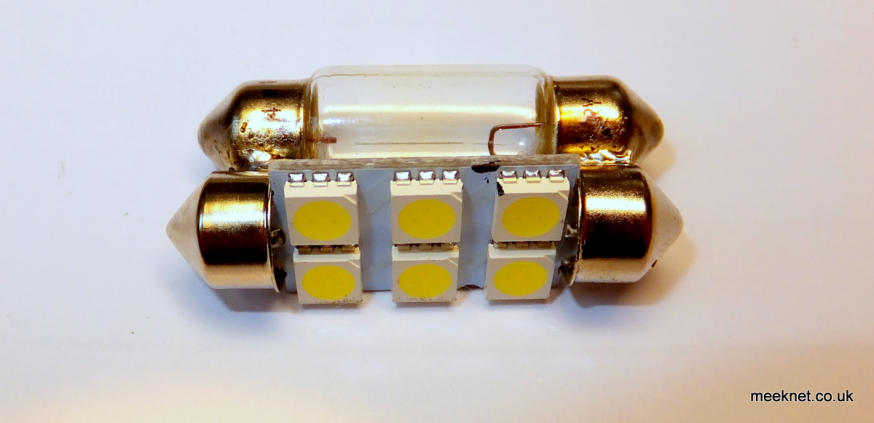

After making error-free FTP sidelights I decided to use the same trick on the Licence-Plate illumination. Just like the FTP sidelights, the

LKM is very fussy about what bulbs are used. Every ‘error-free’ LED festoon bulb I have tried are not error-free, and I tried a few. My next

plan was to

make my own -

and that (eventually) worked with this device:

The above is an Ebay ‘error-free’ LED festoon (which wasn’t error-free) with a 56 Ohm 5W resistor inside a ring-heatsink soldered to the

end caps. This worked and kept working for a year or so until one of the resistor legs fell off due to metal fatigue. It was a bit fiddly to

make, and fiddly to fit back in the enclosure but worked.

But, I came across a much easier plan that Mike in CT showed on one of the Forums - and that was to use a cheap an LED festoon

soldered to a standard Tungsten festoon - a simple idea but very sensible - so here’s how I did it.

I bought a bunch of cheap Ebay festoon LED’s WITHOUT a heatsink and filed the end-caps so that they would take solder:

I’m using extended-life 38mm tungsten festoon bulbs - you don’t want to be soldering new bulbs in if they keep fizzling out

As with the LED festoon, I filed the end-caps to take solder and then tinned it with multicore solder

And then it is just a case of soldering the pair together:

That’s all there is to it - when fitting the pair to the E31 Licence-Plate enclosures it is much easier to fit the LED festoon to the contacts

while holding on to the standard tungsten festoon. I tried a version where I removed the LED end-caps to make the assembly smaller,

but the heat from the tungsten festoon cooked the LED’s!

And this is what they look like - not bad at all - and unless the Tungsten festoon fails it will stay error-free

All done, Time for a Cup of Tea