Timm's Curing The BMW E38 50MPH - 60MPH Shimmy

I hate shimmy, especially the way it tricks you that everything is fine - and the next time you drive the car as soon as you reach 50

MPH you can feel the steering lighten up a bit - and then the steering wheel starts shaking in your hand. It can be soul destroying,

especially after you think you have it sorted. I’ve had eight big BMW’s over 25 years and they have all had a bit of shimmy that has

had to be ‘mended’ - and there’s a sequence of things to do to fix it - rather than just chuck money at it.

The E31, E32 and the E38 7-Series can suffer from the dreaded 'shimmy'. This is a wobble through the steering wheel between the

speeds of 50 MPH - 60 MPH, the speed range is important, other things wobble at different speeds, but shimmy is in this speed

range. It is also important to say that shimmy is a front axle problem, this is because 50-60MPH is the resonant frequency of the

front axle - BMW acknowledges this here.

The shimmies are often an indication of general wear in the steering system and suspension (but not always), the BMW E38 has a

great deal of weight over the front wheels, especially when braking. But don’t be fooled, there are often simple things you can do

to fix it rather than replace suspension components, and we will go through them starting with the cheap things (which often are all

that are needed) - so, let’s get on with it - but don’t forget we are dealing with steering wheel wobble between 50-60 MPH -

other wobbles at other speeds have other causes!

•

Start by puffing the front tyres up!

Yes, under-inflated tyres cause shimmy, BMW discuss the reason for this here, before you do anything inflate them to 42 psi. If that fixes

the problem light a pipe, send me a fiver and put your feet up, your problems are caused by dynamic balance problems within the tyres

(all explained in the article above). My current E31 suffered from this after new tyres were fitted, it took a while to find the problem, but

at 32 psi they caused shimmy, and at anything over 38 psi they were perfect!

•

Shimmy’s that almost pull your arms off are nearly always sticky front brake calliper problems

Shimmy caused by front brake problems are

especially scary, they really pull at your arms and

feel as though the lug bolts have come loose.

When this first happened on my 730i I was

convinced that the bolts were loose, out came the

wheel brace and they were perfect.

But the give-away was that one of the front alloys

was a lot hotter than the other - and when you

spat at the disk is sizzled even though I had been

trundling along like a granny.

Look at the state of that on the right! That’s one of

the front disks from my E31 along with a few pads

(the little ones are from the rear axle) and a few

bushes.

The 840ci Sport has Brembo 4-piston callipers and

they notoriously seize-up as the pistons are

tiddlers and one just doesn’t bother to do anything

half the time - and then you give the brakes a good

poke, the piston pops out a bit and doesn’t retract

again.

The whole brake (pads, calliper and disk) then get

very hot and horrible things happen - bits of pad

get stuck to the disk, shear off and you end up

with a disk that looks like the one on the right.

I bit the bullet and bought new callipers (£400

each) rather than refurb, but that is a viable

option.

To stop this happening give the brakes a damn

good kicking once a week from 70 MPH or so

(make sure there is no-one behind you, the E38

stops pretty quickly). This keeps the pistons

moving freely and also gives the ABS pump a quick

blast as that tends to seize up if ignored for any

length of time.

•

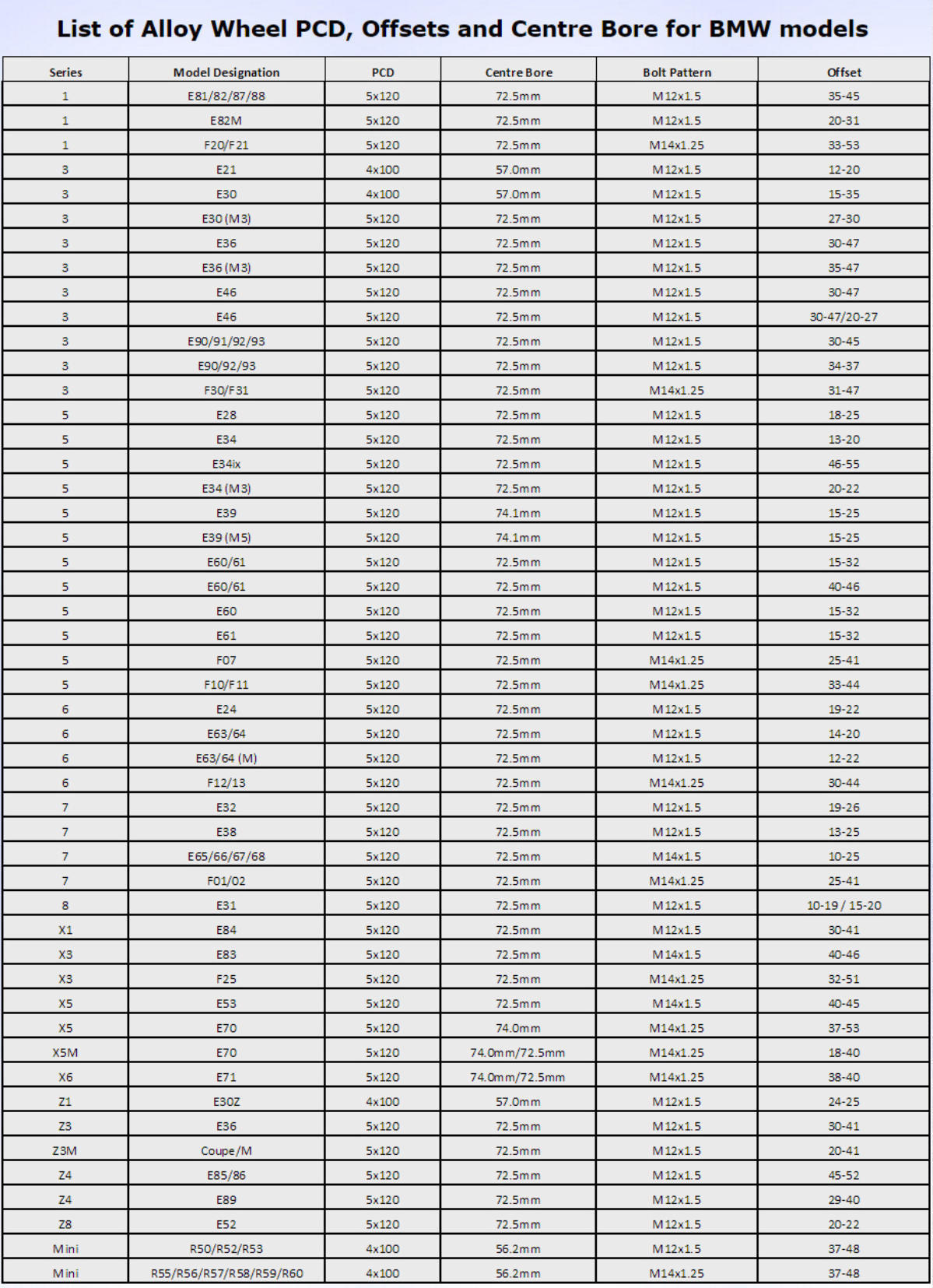

Are you sure those alloys are the right ones?

The best place to start (and often the cheapest) is with the road wheels. The first thing to check is if the wheels are right for

the car. The original wheels for the E38 were 16", they have an offset of 10 -15 and a centre bore of 72.6mm. Here is a list of

offsets of BMW alloys:

•

Wobbles that are NOT shimmies

Vibration that only shows itself when giving the car some welly, especially in 2nd and 3rd gear is quite often due to the propshaft centre

bearing. The bearing is held in a rubber-enclosed housing. When the bearing starts to fail the rubber soon deteriorates and this allows the

propshaft too much lateral movement. The movement causes a vibration through the car, it will eventually get to a point where the

propshaft will start thumping the transmission tunnel. This type of problem always goes away when the throttle is lifted whereas shimmy

doesn't.

If you get a wobble that is only noticeable in 5th gear when you have your foot on the throttle it is almost always due to a single-cylinder

failure on the engine. The lack of a single cylinder on a V8 is not that easy to spot, the power is a bit down and the tick-over is a bit lumpy

but V8's are prone to that anyway. It is most noticeable when on the flat at about 70 MPH when accelerating. The wobble goes immediately

the throttle is lifted. A check of the sparkplugs will show 7 white plugs and one oily one! I have had this fault on my E32 and the repair is

covered here.

If you have fitted an alloy from a model with a different centre bore then you must fit spigot-rings. The only problem is that spigot-rings

are not normally high-precision parts, they wear and corrode and when they do they will not hold the wheel central to the hub. If you are

using spigot-rings consider getting alloys with the correct offset and bore, or, at the very least get new spigot rings.

Even if you are using standard wheels or are using wheels with the correct bore and offset it is worth cleaning the bore and mating

surfaces on both the inside of the wheel and the hub. Where there is corrosion on the hub or wheel the wheel will not mate correctly with

the hub.

Replica alloys usually have a 74.1mm bore and require hub-centric rings, if you have fitted replica alloys ensure these are fitted. Without

the correct rings you will never get rid of wobbles and shimmies for any length of time. Click here for more information on fitting replica

alloys.

•

Tyres

Cheap tyres are often a cause of problems, although these balance fine at low speeds, once they are taking the load of the car and are

rotating at speed they do not retain their shape or were not round in the first place. There is only so much that sticking lead weights on

the rim can compensate for. If you have a lot of lead on your wheels then something is not right in the first place. If you do not have

staggered wheels fitted it is well worth rotating the wheels from the back to the front of the car to see if there is any difference. If it

makes a big difference it is probably a problem with the tyres.

•

Getting rid of shimmy - it’s getting harder and more expensive now - suspension components

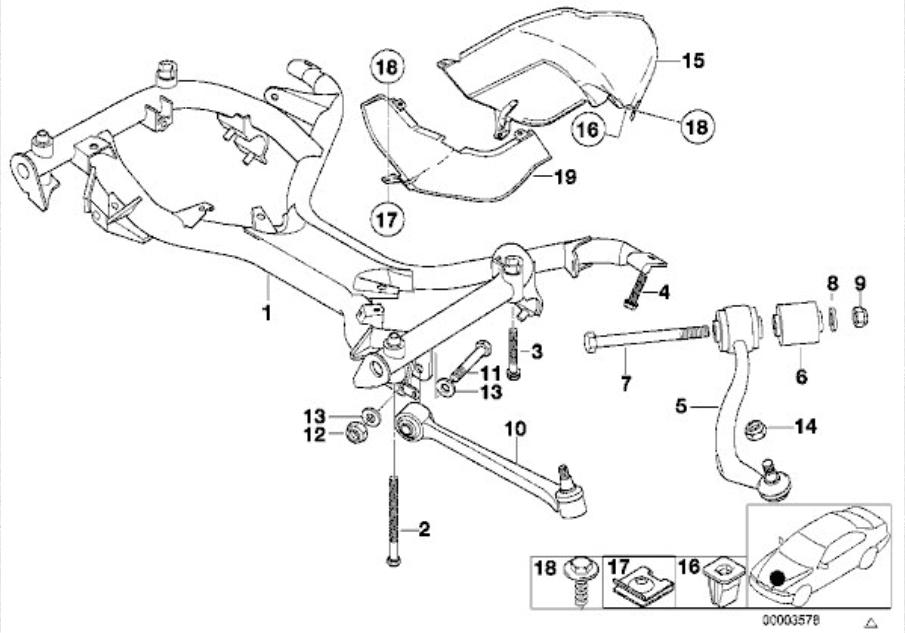

Once all the easy options are out of the way we have to move on to the front suspension components. There is a lot of advice given on

what to change first but in my experience most problems are either removed entirely or at least made significantly better by replacing

the upper arms and rubber bush (items 5 and 6 in the diagram below).

While you are at it you might as well replace the lower arms as well (item 10), the cost is not all that high and is worth doing once the

car is on the lift. A big difference can be made by just changing the bushes (item 6) but normally if the bushes are damaged then the

ball-joints are damaged at the same time. Some like to replace the bushes with polyurethane after-market versions, be aware though

that this will significantly affect the quality of the suspension and may well lead to other component failures.

•

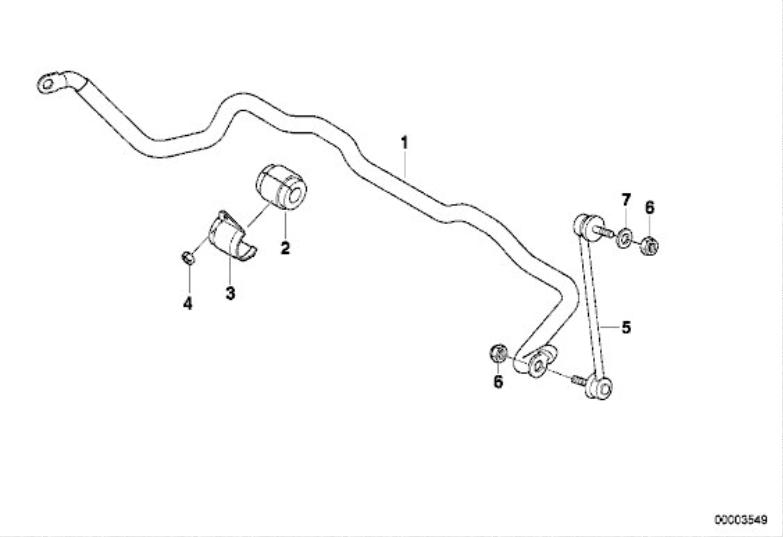

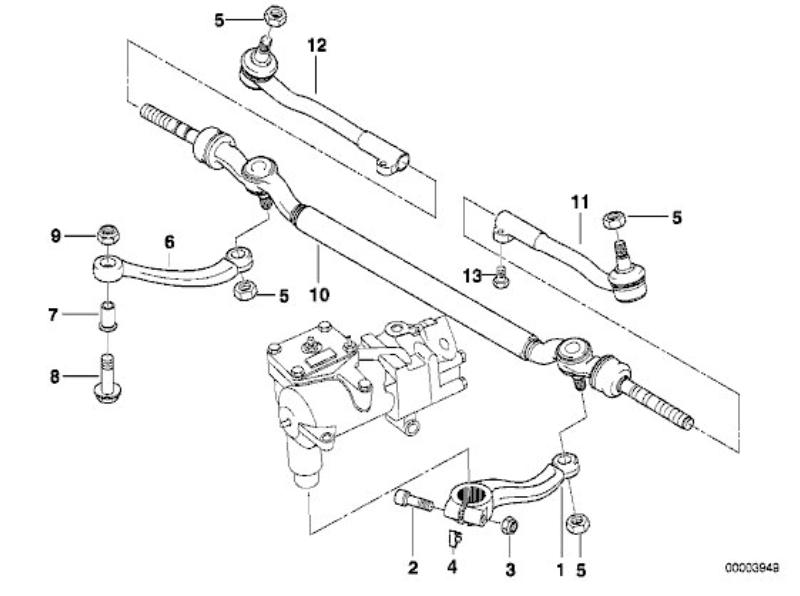

That didn’t fix it? The fixes above will have cured 99% of all problems - so here’s a few more suggestions

We have now covered the possible causes in 99% of the cases I've been involved with. I have heard of miracle fixes where just one

component of the front suspension has been replaced before the usual things have been tried but these are really just one-offs. So, in

order of the most likely here are the remaining candidates:

Front stabiliser joints (item 5)

Centre tie-rod (item 10) Drag link bearing (Items 7 and 8) Tie rods (items 11 and 12)

Once you have got to this point things have got pretty expensive. You can get complete suspension refurbishment kits from Ebay.de, I

have never tried these but have heard good things about them. The last two diagrams only represent 5% of the causes of shimmy so

hopefully you will not need to get to this stage. Unfortunately, if you have just bought an E38 that has shimmy you will not be aware of

what has been changed already. My best advice is don't buy an E38 with shimmy, it can be simple to fix, but it can also be expensive!