Timm's The BMW M60 M62 and M62TU V8 Engine

Working on the BMW V8 engines - it's not as scary as it first seems

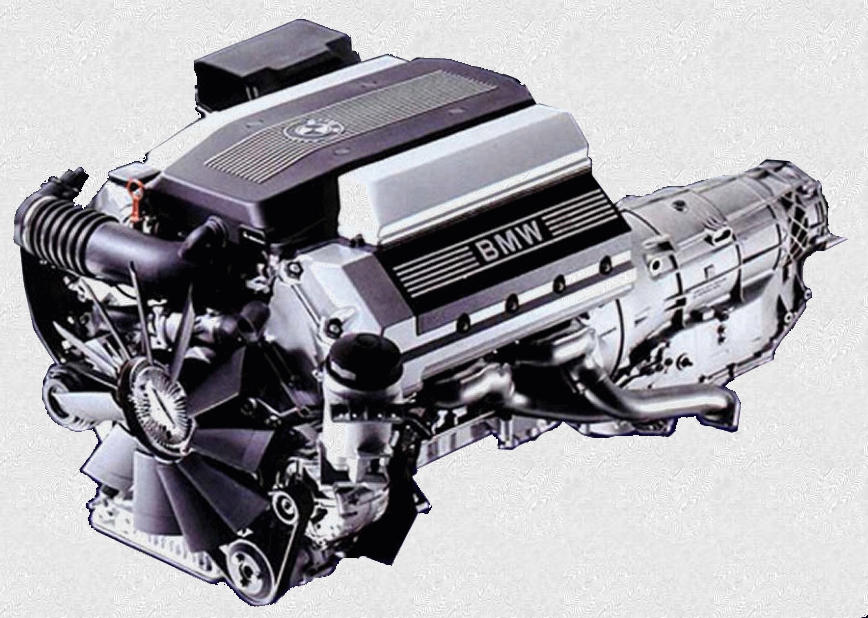

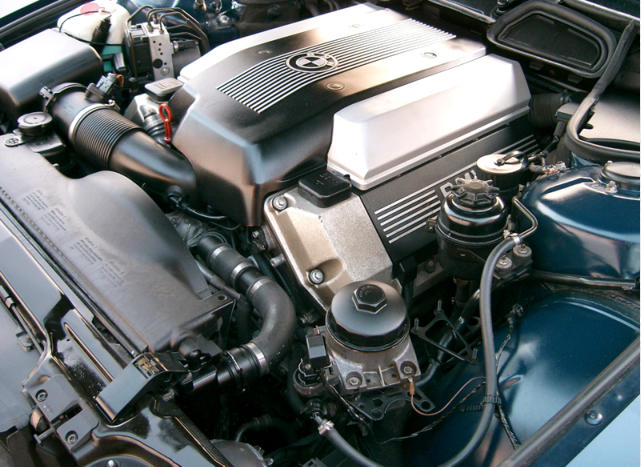

Above is the M60 engine, the first of the modern BMW V8's, it

was sold as a 3-Litre (M60B30) and 4-Litre (M60B40)

History and development

M60

BMW introduced the M60 engine in 1992, fitted to the E32 730i and 740i. It was sold alongside the M30 straight-six and the mighty M70

5-Litre V12 in the E32. It was a radical advancement on these engines as both the M30 and M70 were standard 2-valve per cylinder,

distributor-ignition engines of traditional design - well, apart from the all electronic throttle control on the V12 and some versions of the

M30B35.

The M60 engines introduced 4-valves per cylinder, quad overhead cams, coil-over-plug ignition which dispensed with the distributor and

HT leads, duplex timing chains, 10.5:1 compression, twin-walled exhaust manifolds and cylinder walls hardened using the Nikasil process

rather than using the traditional liner. The new V8 produced more power per litre, but more importantly it was more economical and

produced less pollution. The M60B30 was fitted to my first 7 Series and was a good introduction to this great engine, I'm on my 7th BMW

V8 now with the N62B46.

Mention the M60 engine, even today in 2018, and the next word will be Nikasil. Nikasil was a process to harden the cylinder walls, rather

than using the traditional cylinder liner, the Nikasil process allowed the machined aluminium bores to provide a bearing surface which

promised longevity and better sealing between cylinder and piston. Although the Nikasil process had been used previously with no problems,

the combination of the M60 and fuels with high Sulphur levels softened the cylinder walls. The resultant wear meant a loss of compression

and as the engine was designed without replaceable cylinder liners the engine was effectively scrapped.

Although a great many M60's were re-fitted with a new short-block by BMW, these were initially Nikasil blocks and could have failed again.

BMW's solution was to replace the Nikasil process with a new cylinder-hardening process called Alusil. Around the same period, the Sulphur

levels in fuels was reduced and those engines that suffered bore wear were replaced, and those that were not replaced were not affected

once the Sulphur levels decreased. As Nikasil deterioration resulted in catastrophic engine problems due to bore failure there were no

engines that were affected but kept running for any length of time, and this meant that the Nikasil failure period was limited. It has been

many years now since Nikasil failure was a worry with the M60 engine - further details can be found here.

It might have been expected that the 730i V8 (218 BHP) would have much better performance than the 730i I-6 (185 BHP), and the M30

engined E32 would be dropped - but this was not the case as BMW fitted the V8 models with a 3.23 differential whereas the I-6 730i got the

much shorter 4.1. The result was that the V8 had the same 0-60 MPH performance as the I-6 and most owners of the 730i were not that

interested that the V8 was 5 MPG more frugal.

M62

If the M60 had a shortcoming it was the lack of torque at low revs, especially the 3 Litre M60B30 which really only got going at 4000 RPM.

The long final drive ratio certainly didn't help, especially since the part-throttle gear-changes were made well below the power-band. To

address the lack of performance at low revs the M62 was introduced in 1995.

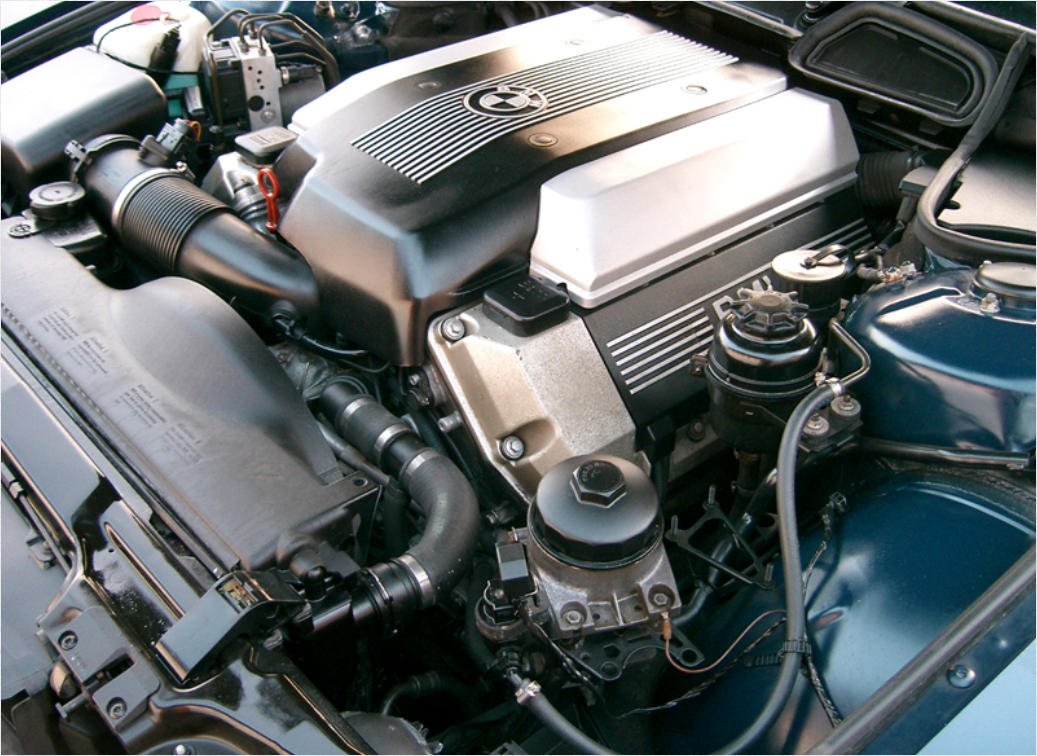

The M62B44 fitted to the 840ci, the long cable across the front of the engine is for cruise control

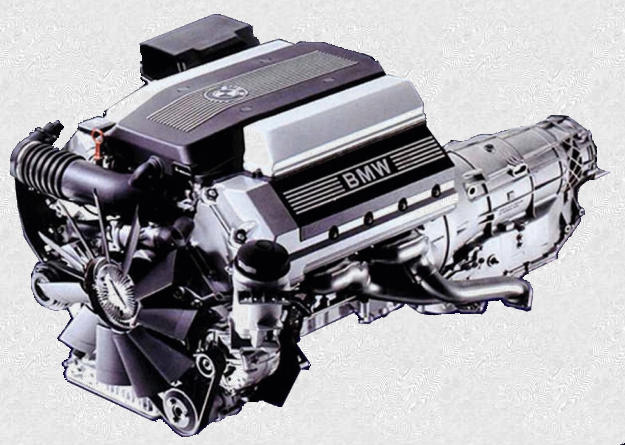

The M62TUB44 fitted to the E38 - The CC, ASC and throttle cables have been replaced with EML

The M62 was produced as the 3.5 Litre M62B35 and the 4.4 Litre M62B44 and fitted to the E31 and E38. The published power for the 4.4

Litre M62 was 286 BHP (sometimes quoted as 282 BHP) which is the same figure as quoted for the 4 Litre M60. Again, BMW changed the

differential from 3.15 to 2.93 when the M62 was introduced (except for the Sport 740i which retained the 3.15) and the acceleration

figures again remained the same.

The same differential ratio change was present on the 8-Series 840ci. When the M62 was introduced in the E31, the rear axle ratio changed

from 2.93 (M60) to 2.81 (M62) - and still the same acceleration figures were stated. Mechanically the M62 lost a couple of useful parts, the

duplex timing chains and the idler sprocket, in their place was added a single timing chain and plastic chain guides. In performance terms,

the M62 produced a hefty amount of torque at lower revs and the more sophisticated DME 5.2 engine management increased fuel

economy.

However, the improvements didn't really make that much difference, especially with the longer final drive, and it wasn't until the M62TUB

was introduced that the performance targets were realised. The DME 5.2 engine management added a lot tighter control of the engine and

the diagnostic capabilities were increased drastically.

M62TUB

The M62TUB44 is really the engine that the M60 aspired to be, it has heaps of low-down torque, is economical and produces much lower

emissions. The main difference was the introduction of variable valve timing on the inlet camshafts (Vanos), this was the source of the flatter

torque-curve and the better fuel economy.

The M62TUB also introduced fully-electronic throttle control (EML), this meant that the ASC and cruise-control actuators were not required,

but more importantly, it meant that the throttle response could be altered depending on driving style. The relation between throttle pedal and

throttle butterfly were not fixed as it is when a cable is used, instead the throttle butterfly could open by different amounts and at different

speeds with the same pedal press depending on driving mode.

This gives the 740i and 540i with the M62TUB44 better performance at all engine speeds. Perversely, the published acceleration remained the

same as did the BHP, owners who have driven both versions would disagree. The added complexity also increased the problems with the V8

with the introduction of 'Vanos noise' (which wasn't terminal although annoying) and failure of the timing solenoids and seals.

Engine details:

More information on all three versions of the V8 can be found below:

M60

M62

M62TUB

Problems with the modern V8:

The M60/M62/M62TUB engines have proved exceptionally reliable - there are many thousands of the Nikasil M60's still in daily use,

maintaining perfect compression. After a shaky start the modern BMW V8's have proved to be an unrivalled success. However, they have a

few weak spots, the most common are listed below:

•

The cooling system overheats and explodes

•

The crankcase ventilation system causes all sorts of problems

•

The valve train makes some scary noises

•

The M62TUB44 can suffer from 'Engine Failsafe' problems

•

The M60 could easily over-fuel and fail to start for days

•

Vacuum leaks causes strange behaviour

Click on the links below for more information and repair instructions:

SEARCH MEEKNET

SEARCH MEEKNET

SEARCH MEEKNET

Timm's The BMW M60 M62 and M62TU

V8 Engine

Working on the BMW V8 engines - it's not as scary

as it first seems

Above is the M60 engine, the first of the modern BMW V8's, it

was sold as a 3-Litre (M60B30) and 4-Litre (M60B40)

History and development

M60

BMW introduced the M60 engine in 1992, fitted to the E32 730i and 740i.

It was sold alongside the M30 straight-six and the mighty M70 5-Litre V12

in the E32. It was a radical advancement on these engines as both the

M30 and M70 were standard 2-valve per cylinder, distributor-ignition

engines of traditional design - well, apart from the all electronic throttle

control on the V12 and some versions of the M30B35.

The M60 engines introduced 4-valves per cylinder, quad overhead cams,

coil-over-plug ignition which dispensed with the distributor and HT leads,

duplex timing chains, 10.5:1 compression, twin-walled exhaust manifolds

and cylinder walls hardened using the Nikasil process rather than using

the traditional liner. The new V8 produced more power per litre, but more

importantly it was more economical and produced less pollution. The

M60B30 was fitted to my first 7 Series and was a good introduction to this

great engine, I'm on my 7th BMW V8 now with the N62B46.

Mention the M60 engine, even today in 2018, and the next word will be

Nikasil. Nikasil was a process to harden the cylinder walls, rather than

using the traditional cylinder liner, the Nikasil process allowed the

machined aluminium bores to provide a bearing surface which promised

longevity and better sealing between cylinder and piston. Although the

Nikasil process had been used previously with no problems, the

combination of the M60 and fuels with high Sulphur levels softened the

cylinder walls. The resultant wear meant a loss of compression and as the

engine was designed without replaceable cylinder liners the engine was

effectively scrapped.

Although a great many M60's were re-fitted with a new short-block by

BMW, these were initially Nikasil blocks and could have failed again.

BMW's solution was to replace the Nikasil process with a new cylinder-

hardening process called Alusil. Around the same period, the Sulphur

levels in fuels was reduced and those engines that suffered bore wear

were replaced, and those that were not replaced were not affected once

the Sulphur levels decreased. As Nikasil deterioration resulted in

catastrophic engine problems due to bore failure there were no engines

that were affected but kept running for any length of time, and this

meant that the Nikasil failure period was limited. It has been many years

now since Nikasil failure was a worry with the M60 engine - further

details can be found here.

It might have been expected that the 730i V8 (218 BHP) would have

much better performance than the 730i I-6 (185 BHP), and the M30

engined E32 would be dropped - but this was not the case as BMW fitted

the V8 models with a 3.23 differential whereas the I-6 730i got the much

shorter 4.1. The result was that the V8 had the same 0-60 MPH

performance as the I-6 and most owners of the 730i were not that

interested that the V8 was 5 MPG more frugal.

M62

If the M60 had a shortcoming it was the lack of torque at low revs,

especially the 3 Litre M60B30 which really only got going at 4000 RPM.

The long final drive ratio certainly didn't help, especially since the part-

throttle gear-changes were made well below the power-band. To address

the lack of performance at low revs the M62 was introduced in 1995.

The M62B44 fitted to the 840ci, the long cable across the front of the engine is for cruise

control

The M62TUB44 fitted to the E38 - The CC, ASC and throttle cables have been replaced with EML

The M62 was produced as the 3.5 Litre M62B35 and the 4.4 Litre M62B44

and fitted to the E31 and E38. The published power for the 4.4 Litre M62

was 286 BHP (sometimes quoted as 282 BHP) which is the same figure as

quoted for the 4 Litre M60. Again, BMW changed the differential from 3.15

to 2.93 when the M62 was introduced (except for the Sport 740i which

retained the 3.15) and the acceleration figures again remained the same.

The same differential ratio change was present on the 8-Series 840ci.

When the M62 was introduced in the E31, the rear axle ratio changed from

2.93 (M60) to 2.81 (M62) - and still the same acceleration figures were

stated. Mechanically the M62 lost a couple of useful parts, the duplex

timing chains and the idler sprocket, in their place was added a single

timing chain and plastic chain guides. In performance terms, the M62

produced a hefty amount of torque at lower revs and the more

sophisticated DME 5.2 engine management increased fuel economy.

However, the improvements didn't really make that much difference,

especially with the longer final drive, and it wasn't until the M62TUB was

introduced that the performance targets were realised. The DME 5.2

engine management added a lot tighter control of the engine and the

diagnostic capabilities were increased drastically.

M62TUB

The M62TUB44 is really the engine that the M60 aspired to be, it has

heaps of low-down torque, is economical and produces much lower

emissions. The main difference was the introduction of variable valve

timing on the inlet camshafts (Vanos), this was the source of the flatter

torque-curve and the better fuel economy.

The M62TUB also introduced fully-electronic throttle control (EML), this

meant that the ASC and cruise-control actuators were not required, but

more importantly, it meant that the throttle response could be altered

depending on driving style. The relation between throttle pedal and

throttle butterfly were not fixed as it is when a cable is used, instead the

throttle butterfly could open by different amounts and at different speeds

with the same pedal press depending on driving mode.

This gives the 740i and 540i with the M62TUB44 better performance at all

engine speeds. Perversely, the published acceleration remained the same

as did the BHP, owners who have driven both versions would disagree. The

added complexity also increased the problems with the V8 with the

introduction of 'Vanos noise' (which wasn't terminal although annoying)

and failure of the timing solenoids and seals.

Engine details:

More information on all three versions of the V8 can be found below:

M60

M62

M62TUB

Problems with the modern V8:

The M60/M62/M62TUB engines have proved exceptionally reliable - there

are many thousands of the Nikasil M60's still in daily use, maintaining

perfect compression. After a shaky start the modern BMW V8's have

proved to be an unrivalled success. However, they have a few weak spots,

the most common are listed below:

•

The cooling system overheats and explodes

•

The crankcase ventilation system causes all sorts of problems

•

The valve train makes some scary noises

•

The M62TUB44 can suffer from 'Engine Failsafe' problems

•

The M60 could easily over-fuel and fail to start for days

•

Vacuum leaks causes strange behaviour

Click on the links below for more information and repair instructions:

SEARCH MEEKNET

SEARCH MEEKNET