TIMM'S BMW E38 SEAT-BASE REPAIR

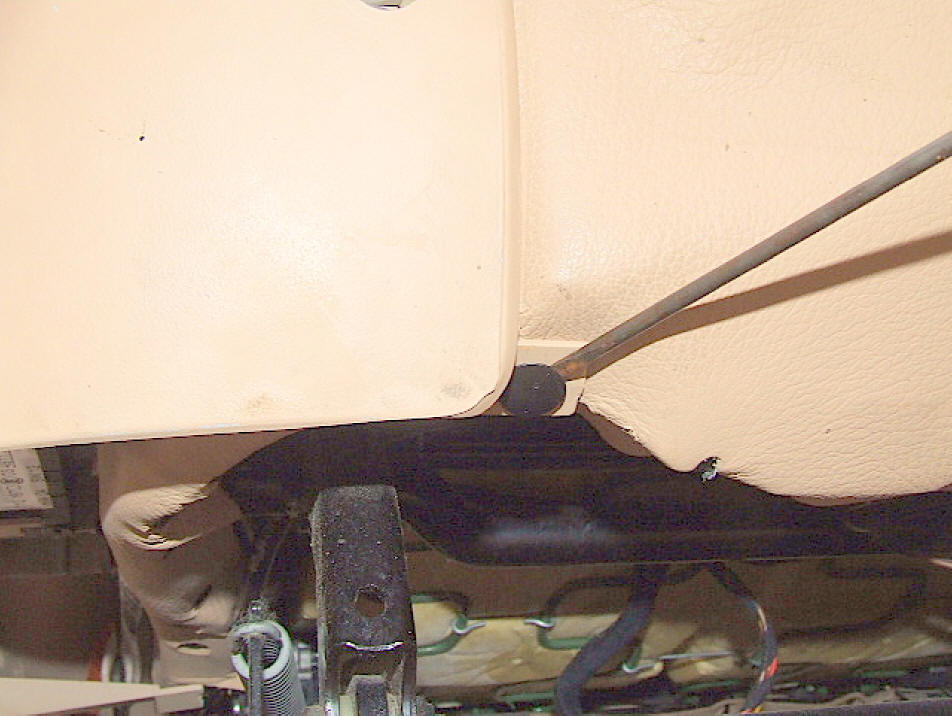

Have you got a seat base that looks like

this?

Not only was the base floppy and not fitting snugly against the leather, the

switches didn't operate correctly....a slight poke on the recline button and the

seat would keep reclining until it hit the end-stop. The big switch was

decidedly floppy as well.

We need to release the remaining fastener at the front of the seat base. There

is a small expanding collet around the front of the seat base.....ping this out

with a flat-bladed screwdriver:

The seat base can now be moved away from the front of the seat so that access

can be made to the switch assembly. The switch assembly is held onto the plastic

base with four clips. If you have a floppy switch assembly, remove the two

control knobs, these pull away from the base, use two flat-bladed screwdrivers

if the knobs are too tight to remove by hand.

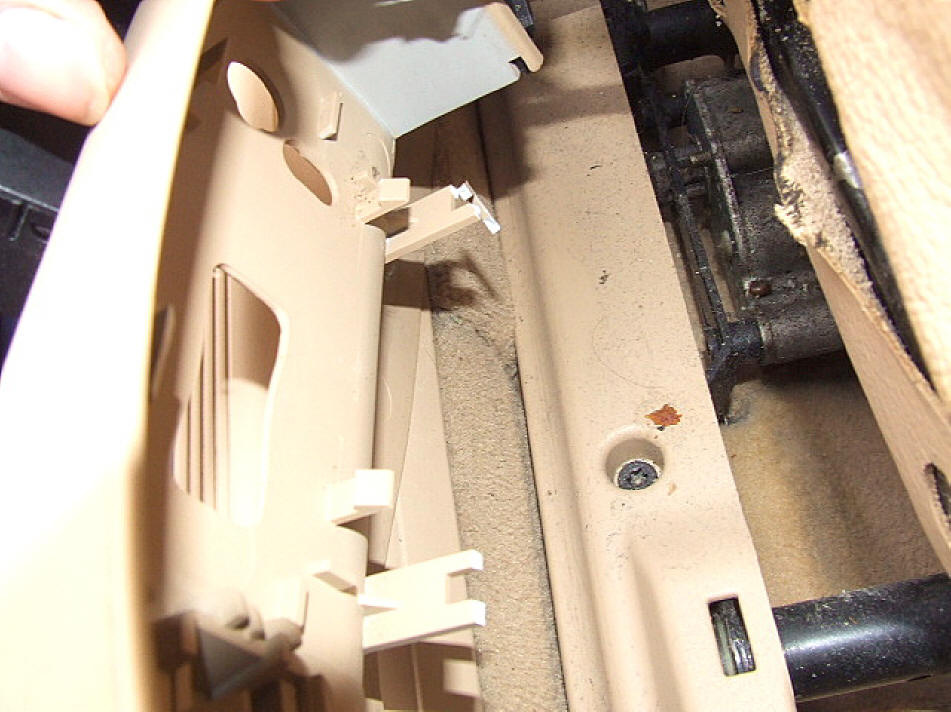

Once the knobs are off, the switch assembly can be detached from the clips, two

at the top, two at the bottom. The reason for the floppy switches are

immediately obvious, although the top clips are OK, the bottom ones have broken

at the ends:

The easiest way to get around the broken clip problem is to draw a thin bead of

Superglue along the clips and then push the switch assembly back onto the clips.

The plastic of the base and the switch assembly work well with Superglue and it

was as firm as you like in a few seconds. Push the knobs back on while holding

the switch assembly from behind and it is all lovely again.

The seat base wobblyness was due to the upper fixing, this seems a bit weak, and

in this case the screw still had a bit of seat base on it when it was removed:

There are a number of ways to fix this, I started with gluing a large washer

into the remains of the fixing point:

That was a bit fiddly, especially because a reasonable amount of pressure is put

on the fixing. The washer needs to be clamped by the fixing screw to be

effective, the problem is getting it into the right place and tightening the

screw without putting side pressure on the washer.

I found a better plan was to use one of the 'U' shaped fixings with a

self-tapping screw-hole in the middle that are normally used for fixing trim to

sheet metal. I glued this in place with two-part Epoxy (Araldite Rapid) also

filling up the spaces where the plastic had snapped off and allowed it to set

for 30 minutes.

Fit the screw a single turn into the 'U' fixing, clip the 'U' fixing into the

broken channel in the seat base and align the seat base in the correct position.

Once the seat base is screwed back in place and the lower collet is pushed back

in place, the 'U' fixing clamps quite successfully onto the base and all is

lovely again:

All done.....time for a cup of tea