BMW E38

Timm's The BMW M60 M62 and M62TU Engine

The Cooling System

When fitted to the E31, E32, E38 and E39, the cooling system contains 12 litres of coolant which is circulated by a belt-driven centrifugal

water pump. The system is pressurised at operating temperature to a maximum of 2 Bar, regulated by a pressure-relief valve in the filler

cap. The pressurisation allows the coolant to stay liquid over boiling temperature, and this is required as the M62 operates at 105C when

fitted to the E38/E39. A thermostat is fitted to the system to maintain a constant block temperature, it opens to allow the coolant to flow

through the radiator, be cooled and returned to the block. If the radiator outlet temperature increases past 95C the main viscous-coupled fan

produces much greater airflow to remove the heat from the radiator. If the radiator outlet temperature increases past 104C, the auxiliary fan

(usually used for the air-conditioning system) runs at full speed to provide additional air flow.

As the coolant temperature rises from cold, the volume of the coolant increases, to allow for this, an expansion tank is fitted to the radiator

cowl. The expansion tank is only partially filled with coolant to allow for the expanding liquid. The cap fitted to expansion tank will allow

excess coolant to be expelled once the pressure exceeds 2 Bar. A separate coolant circuit (the feed taken before the thermostat) is used for

cabin heating. The flow is controlled by two water valves (called heater valves) and directed to the heater matrix which comprises two

halves, one side for the driver, the other for the passenger. In addition to the flow provided by the main water pump, there is an auxiliary

water pump for the heater system. This increases the flow at idle and allows the heater system to be used when the engine is not running as

the auxiliary pump circulates coolant around the block and heater matrix.

The thermostat used on the M62 and M62TUB when fitted to the E38 and E39 is set to open at 108C but is also influenced by an internal

heater. This allows the opening of the thermostat to be controlled between 85C and 108C by applying power to the internal heater. As a

generalisation, the thermostat is set to open at 108C when cruising to increase economy and set to open at 85C when full-power is required

to stop detonation.

Cooling system problems

The cooling system on the V8's is perfectly adequate, well, it was perfectly adequate when the car was new. And that's where the problem

lies, parts wear out, get fatigued and ignored and then the system lets go with a loud pop.

Parts that leak coolant or cause explosions of steam

The expansion tank gets brittle after a few years, the combination of heat and pressure eventually splits the plastic. The crack is often in the

side that faces the radiator and is difficult to see, but usually they go with a bang and it's pretty obvious where the problem is. Replacement

of the expansion tank is a simple fix.

Out comes another failed expansion tank in a 2000 740i fitted with the M62TUB44

Where steam suddenly appears from the firewall you can be sure that one of the heater hoses has failed. There are two that are more prone

than the others, and these are the hoses that run from the rear of the engine to the heater valves and the heater matrix. This is due to the

constant movement of the engine in relation to the firewall which stretches as fatigues the hose. Replacement of the heater hoses well in

advance will stop this happening. In the same area is the heater valves and auxiliary water pump, the unions can fail due to the same

fatigue.

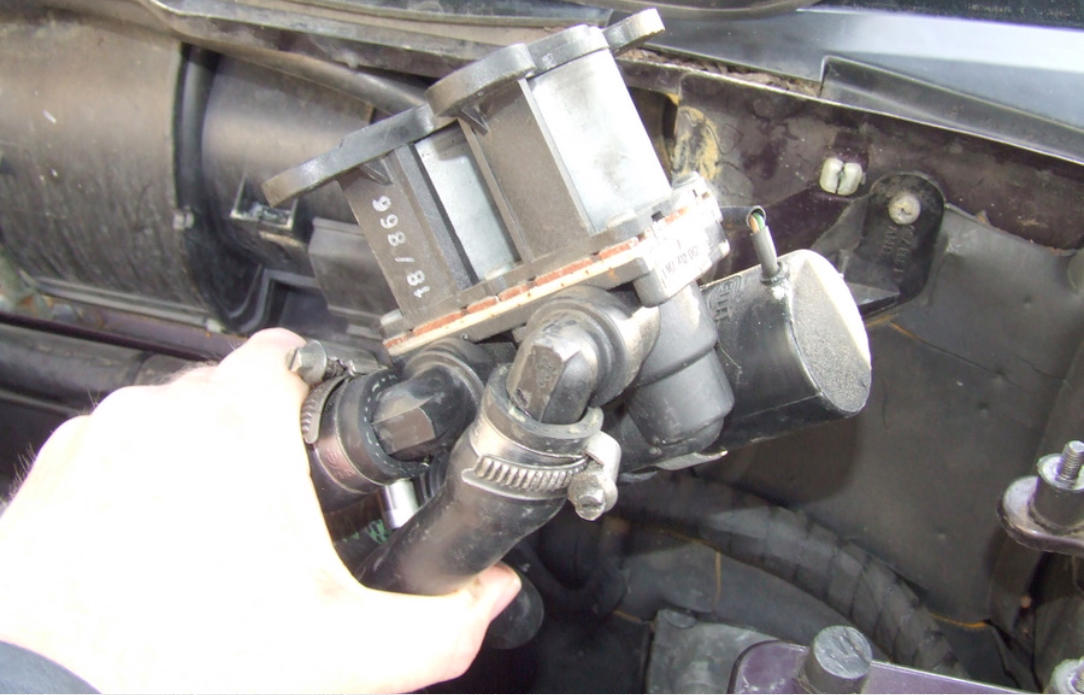

The heater valves and auxiliary pump wrestled from the housing in a 1999 840ci fitted with the M62B44

The water pump on the V8's can fail, usually the front bearing and seal. Once the front seal starts leaking the bearing is robbed of

lubrication, and this rapidly deteriorates to a point where the input shaft starts rattling around, steam shoots out and the fan blades much a

hole in the radiator. If there is any movement felt in the viscous-coupled fan (which is suspended by the water pump shaft) the pump must

be replaced before expensive damage occurs.

The brown spray is the remains of the water pump front bearing mixed with coolant on a 1997 840ci M62B44

Coolant leaking from the left-hand side of the radiator on the M60 M62 engines is very often due to a cracked radiator top-hose stem. The

radiators on the E31, E32 and pre-facelift E38's and E39's become brittle and often crack under the top hose where the Jubilee clip is fitted.

The only repair is the replacement of the radiator. The M62TUB engines introduced a twist-to-lock fitting so that no Jubilee clip is required.

The top hose boss is often a source of failure on the M60 and M62 engines where the Jubilee clip is fitted

The list above covers the main problems with exploding and leaking parts of the cooling system, other parts can fail including the remainder

of the hoses, the heater matrix itself including the o-rings on the manifold unions and the cross-pipes that run from the water pump to the

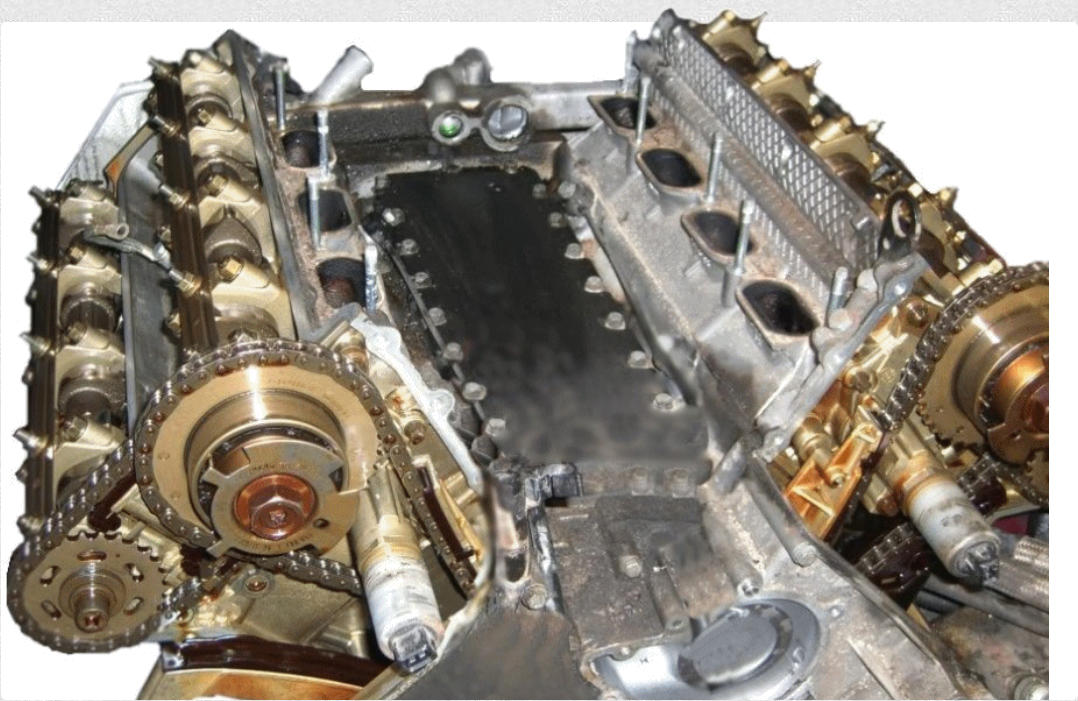

cross-pipe at the rear of the engine. In hotter climates, the valley-pan gasket can fail and produce a leak that is difficult to trace as the

coolant runs down the back of the engine and on to the gearbox bell-housing.

Of the problems above, replacing the heater hoses and the expansion tank goes a long way to making the cooling system a lot more reliable.

However, bleeding the coolant system after repair is absolutely essential. Failure to bleed the cooling system correctly will lead to the

problems experienced in the next section, overheating!

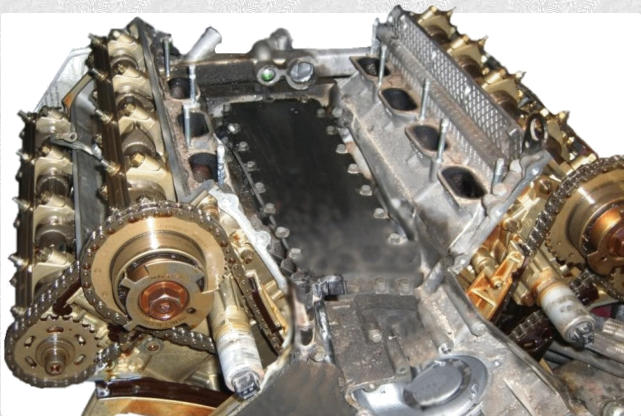

The valley-pan cover can be seen here in the 'V' of the engine (M62TUB44). Not usually a problem in the UK

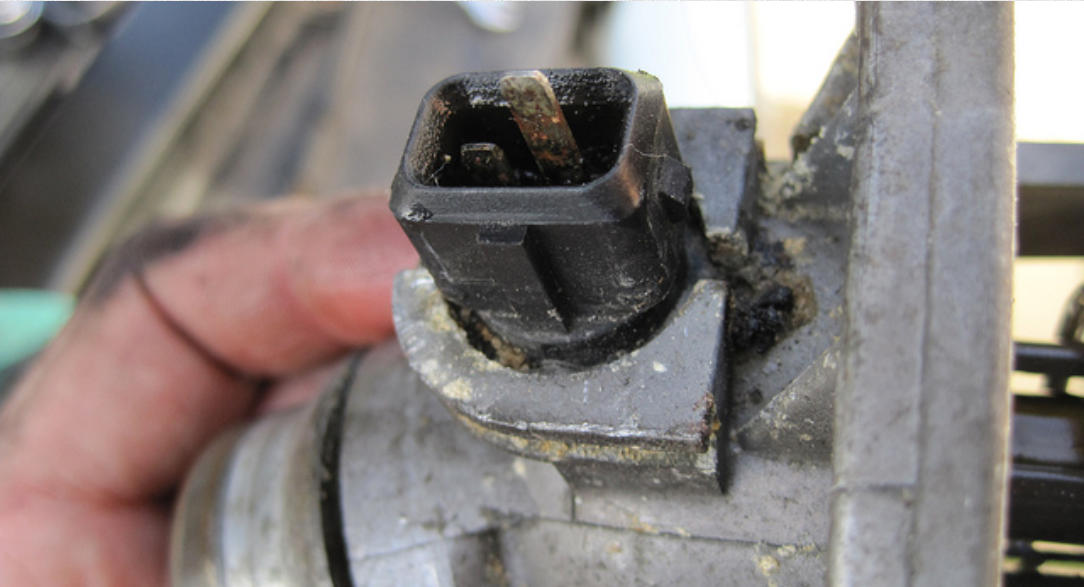

One final leakage area which is only found on the E38/E39 is the thermostat housing. This leak is very difficult to find as the coolant wicks

up the thermostat heater loom and into the E-Box where it drips into the main ECU. Often, the first sign that something wrong is an

instrument cluster warning saying the engine is running into 'Engine Failsafe' mode. A few days later this will stop the engine running

altogether.

A failed seal on the heater connection allows coolant to leak into the ECU leading to Engine Failsafe mode

Overheating

If your temperature gauge starts heading for the red zone - stop immediately - and if you can't stop, put the heater on the highest

temperature and the fan on full speed to pull heat from the engine. This can also help diagnose the problem, if you get no heat from the

heater then no coolant is circulating. If running the heater at full reduces the coolant temperature (as seen on the gauge), then a lack of

cooling efficiency is more likely. As long as the car is not driven any further with the gauge in the red then normally no engine damage will

occur. But drive a couple of miles and severe engine damage will be seen with failure of the head gaskets being the start of a lot of bad

news.

This is a big subject on the V8's, read any E38 Forum and there are endless posts describing temperature gauges that inexplicably head

towards the red zone. There are two main reasons for the problem, not enough air-flow and failure to move coolant around the system -

each problem has its own symptoms. Finding the cause of overheating can be difficult, but there are usually some clues. If the car overheats

after work has been done on the cooling system, or it was drained during other work, then the cause is often air trapped in the system which

stops the coolant circulating. Where overheating happens gradually, especially on very hot days, then a lack of efficiency (due to sediment in

the radiator, damaged radiator fins etc) is usually the cause.

Certain cooling problems fail in unique ways making diagnosing the fault easier, these are all explained below. It is worth saying at this point

that it is essential that there are no leaks in the system (see previous section), leaks not only lose coolant, but when the engine cools they

introduce air into the system - and often into areas that can stop the coolant circulating. The water pump is a centrifugal type and it will fail

to operate if air is introduced.

Overheating at idle and slow speed

Overheating at slow speed and idle is usually due to the lack of airflow through the radiator (but not always). At idle and slow speed the

airflow through the main radiator is not sufficient to remove the heat from the coolant. To increase the airflow there is a viscous-coupled fan

attached to the water pump.

The viscous-coupled fan on a 740i fitted with the M62TUB44, the radiator shroud has been removed for clarity

The fan is attached to the water pump and driven by the serpentine belt from the crankshaft pulley. The finned part in the centre of the fan

is a viscous coupling. This allows the fan to freewheel when not required, and then lock when additional airflow is needed for cooling. What

is not fully understood is that the locking mechanism is controlled by the radiator temperature and not the engine temperature. For the fan

to operate correctly the coolant must flow through the radiator, if the coolant is not circulating (due to an air lock or a failed thermostat)

then the fan will refuse to move air at any volume.

When working correctly, the fan will idle when the radiator temperature is below 95C (+/- 4C) and can be stopped from rotating with a

rolled-up newspaper. Once above this temperature, the viscous coupling will lock and move great volumes of air through the radiator - this is

quite noticeable as the noise level increases and the airflow can be felt across the engine. It is worth noting that the viscous coupling also

locks up when the engine is started from cold for 30 seconds or so. As already mentioned, the air-conditioning system has its own cooling

fan in front of the radiator, this is called the auxiliary fan. E31's, pre-facelift E38's and E39's have a two speed fan, normal speed is used by

the air-conditioning, high speed is commanded by the DME (engine computer) when the radiator outlet temperature exceeds 99C.

The auxiliary fan on an 840ci Sport - used for both the A/C and saves the day when overheating

At slow road speed or at idle, if the temperature gauge is seen to leave the centre position and head to the red, and then return to the

centre in regular cycles - this often indicates failure of the viscous coupled fan. The reason for this is that the viscous coupled fan is not

providing sufficient airflow through the radiator, the coolant temperature increases and the temperature gauge starts climbing. At a radiator

outlet temperature of 99C the auxiliary fan cuts in at high speed, reduces the coolant temperature and the temperature gauge returns to the

centre.

If the auxiliary fan has also failed (often not noticeable except the air conditioning is weak), the temperature will keep rising until the coolant

system fails. The above is only true if the failure is at slow speed or idle. At higher speeds (>30 MPH), the forward motion is enough to

provide enough airflow through the radiators.

Overheating at any road speed

Overheating when driving at a good speed is usually due to poor circulation of coolant rather than a lack of airflow through the radiator. Poor

circulation can be due to a number of factors, a failed thermostat, a failed water pump (unusual, but has happened), a blockage or a

shortage of coolant.

Bleeding

If you have just replaced a part of the cooling system and had to refill, then the possibility is that there is air still in the system. Some cars

prove really difficult to bleed, but this is usually due to a coolant leak. Some coolant leaks go unnoticed as they leave no trace, but if coolant

is getting out, air is getting in. Air in the cooling system can stop the water pump operating correctly as the air can sit between the pump

and the thermostat. It is important, when replacing the thermostat, to get the bleed hole at the top - this allows air to pass through the

system rather than getting stuck:

The bleed hole on the thermostat shown above is at the front - always place the thermostat so this is uppermost.

There are many different methods to bleed the V8 cooling system, but on all the V8's I have owned and worked on, the methods shown here

and here have never failed. The system on the E38/M62 operates above boiling point (105 C), so bleeding with the expansion tank cap

removed will only expel coolant once the engine reaches running temperature. Bleeding with the cap removed will introduce more air into

the system.

Head gasket failure?

Failure of the head gasket(s) on the M60/M62/M62TU is very rare if the engine has never over-heated, but many heads have been removed

only to find the gaskets intact and the block and head in good condition. This usually happens when the engine keeps refusing to bleed

correctly and the temperature rises past the centre each time. As previously discussed, this can be due to a coolant leak that is not

discovered. Before contemplating removing the heads, replace the coolant (as this may be contaminated) and use a block tester (shown

below) to check for any exhaust gasses in the coolant:

A block tester is essential for finding failed head gaskets. The fluid changes colour if exhaust gasses are detected.

Blockages

As already discussed, the most common blockage is air which often gets trapped between the thermostat and water pump. If the coolant is

not circulating the radiator will stay cool and the bottom radiator hose will remain just warm. As the radiator outlet temperature is low,

neither the viscous-coupled fan or the auxiliary fan will run and the engine will rapidly overheat.

The obvious place to start when the coolant is not circulating is the thermostat. Thermostats can fail closed, and this will stop the coolant

circulating through the main radiator. However, a failed thermostat will not stop the coolant circulating the heater matrix - if you have heat

in the cabin but no circulation through the radiator then the thermostat is likely to have failed closed. If you have no heat in the cabin and

no circulation through the radiator, then there is either an air-lock at the water pump, a mechanical failure of the water pump or a blockage.

Failure of the water pump to circulate the coolant is very rare, however, there was a period where the water pump vanes were made of

plastic and these could disintegrate. If the water pump is replaced, check that the vanes have not disappeared, if they have then a

comprehensive flushing will be required to get the pieces out of the system. Make sure the replacement has a metal impeller as shown

below:

A failed BMW water pump - the plastic impellers can fail and block the coolant system.

Where the water pump and thermostat has been replaced and the coolant still fails to circulate then the main radiator needs to be checked

by flushing. Older radiators can become blocked with rust where incorrect coolant has been used (or just plain water is in the system). If the

radiator is much hotter at the top in comparison to the bottom then it is quite likely the radiator is partially blocked. Where is radiator is

found to be partially blocked this usually means the radiator has reached the end of its life. Although the radiator can be flushed, the

blockage is usually oxides that have been produced by decomposition of the internal structure and after flushing the radiator may leak or

burst. The best course of action is to remove the radiator and fully flush the system before replacement.

Don't forget the temperature sensor

Where the temperature gauge moves extremely rapidly in the first few minutes of running, the fault is often due to a faulty temperature

sensor or the wiring to it. On facelift (post 10/98) E38's and E39's, the temperature sensor wiring shares the same loom as the heater wires

for the mapped thermostat. It is well known that the connector on the heater can fail and leak coolant - this not only wicks up the loom to

cause problems with the ECU, but also can degrade the temperature gauge wiring giving false readings. The temperature sensor itself can

also fail in a way to provide erratic temperature readings. Where the movement of the gauge makes no sense and there are no other signs

of overheating suspect the sensor.

Conclusion on cooling system

The cooling system on the V8's can certainly cause problems - some are simple as when something explodes and can be replaced. Other

problems, as discussed above, can cause misery, especially when bleeding fails to solve intermittent overheating. These problems are very

often due to small leaks that are not noticed - if you are needing to 'top-up' the coolant regularly you have a leak. You will not cure

overheating problems until the leak is found and rectified. The reason for this is that the cooling system runs at internal temperatures

that are above the boiling point of the coolant, even on engines fitted with an 85C thermostat. If you have a small leak, the system will not

pressurise to the required 2 Bar. In this situation the coolant will boil at the cylinder walls and produce gasses that stop the water pump

operating correctly, and this will allow the engine to overheat - especially when the thermostat is fitted with the bleed-hole at the bottom

rather than at the top.

Before worrying about failed head gaskets, it is much more likely that there is something wrong with the cooling system. It is very unusual

for the V8 head gaskets to fail - it is usual for the system to acquire small leaks, for the viscous-coupled fan to fail, to have air trapped in

places from which it is difficult to remove and the temperature sensor to lie - don't panic, it's usually something simple!

SEARCH MEEKNET

SEARCH MEEKNET

Timm's The BMW M60 M62 and M62TU

Engine

The Cooling System

When fitted to the E31, E32, E38 and E39, the cooling system contains 12

litres of coolant which is circulated by a belt-driven centrifugal water

pump. The system is pressurised at operating temperature to a maximum

of 2 Bar, regulated by a pressure-relief valve in the filler cap. The

pressurisation allows the coolant to stay liquid over boiling temperature,

and this is required as the M62 operates at 105C when fitted to the

E38/E39. A thermostat is fitted to the system to maintain a constant block

temperature, it opens to allow the coolant to flow through the radiator, be

cooled and returned to the block. If the radiator outlet temperature

increases past 95C the main viscous-coupled fan produces much greater

airflow to remove the heat from the radiator. If the radiator outlet

temperature increases past 104C, the auxiliary fan (usually used for the

air-conditioning system) runs at full speed to provide additional air flow.

As the coolant temperature rises from cold, the volume of the coolant

increases, to allow for this, an expansion tank is fitted to the radiator

cowl. The expansion tank is only partially filled with coolant to allow for

the expanding liquid. The cap fitted to expansion tank will allow excess

coolant to be expelled once the pressure exceeds 2 Bar. A separate

coolant circuit (the feed taken before the thermostat) is used for cabin

heating. The flow is controlled by two water valves (called heater valves)

and directed to the heater matrix which comprises two halves, one side

for the driver, the other for the passenger. In addition to the flow provided

by the main water pump, there is an auxiliary water pump for the heater

system. This increases the flow at idle and allows the heater system to be

used when the engine is not running as the auxiliary pump circulates

coolant around the block and heater matrix.

The thermostat used on the M62 and M62TUB when fitted to the E38 and

E39 is set to open at 108C but is also influenced by an internal heater.

This allows the opening of the thermostat to be controlled between 85C

and 108C by applying power to the internal heater. As a generalisation,

the thermostat is set to open at 108C when cruising to increase economy

and set to open at 85C when full-power is required to stop detonation.

Cooling system problems

The cooling system on the V8's is perfectly adequate, well, it was perfectly

adequate when the car was new. And that's where the problem lies, parts

wear out, get fatigued and ignored and then the system lets go with a

loud pop.

Parts that leak coolant or cause explosions of steam

The expansion tank gets brittle after a few years, the combination of heat

and pressure eventually splits the plastic. The crack is often in the side

that faces the radiator and is difficult to see, but usually they go with a

bang and it's pretty obvious where the problem is. Replacement of the

expansion tank is a simple fix.

Out comes another failed expansion tank in a 2000 740i fitted with the

M62TUB44

Where steam suddenly appears from the firewall you can be sure that one

of the heater hoses has failed. There are two that are more prone than

the others, and these are the hoses that run from the rear of the engine

to the heater valves and the heater matrix. This is due to the constant

movement of the engine in relation to the firewall which stretches as

fatigues the hose. Replacement of the heater hoses well in advance will

stop this happening. In the same area is the heater valves and auxiliary

water pump, the unions can fail due to the same fatigue.

The heater valves and auxiliary pump wrestled from the housing in a 1999

840ci fitted with the M62B44

The water pump on the V8's can fail, usually the front bearing and seal.

Once the front seal starts leaking the bearing is robbed of lubrication, and

this rapidly deteriorates to a point where the input shaft starts rattling

around, steam shoots out and the fan blades much a hole in the radiator.

If there is any movement felt in the viscous-coupled fan (which is

suspended by the water pump shaft) the pump must be replaced before

expensive damage occurs.

The brown spray is the remains of the water pump front bearing mixed

with coolant on a 1997 840ci M62B44

Coolant leaking from the left-hand side of the radiator on the M60 M62

engines is very often due to a cracked radiator top-hose stem. The

radiators on the E31, E32 and pre-facelift E38's and E39's become brittle

and often crack under the top hose where the Jubilee clip is fitted. The

only repair is the replacement of the radiator. The M62TUB engines

introduced a twist-to-lock fitting so that no Jubilee clip is required.

The top hose boss is often a source of failure on the M60 and M62 engines

where the Jubilee clip is fitted

The list above covers the main problems with exploding and leaking parts

of the cooling system, other parts can fail including the remainder of the

hoses, the heater matrix itself including the o-rings on the manifold

unions and the cross-pipes that run from the water pump to the cross-

pipe at the rear of the engine. In hotter climates, the valley-pan gasket

can fail and produce a leak that is difficult to trace as the coolant runs

down the back of the engine and on to the gearbox bell-housing.

Of the problems above, replacing the heater hoses and the expansion tank

goes a long way to making the cooling system a lot more reliable.

However, bleeding the coolant system after repair is absolutely essential.

Failure to bleed the cooling system correctly will lead to the problems

experienced in the next section, overheating!

The valley-pan cover can be seen here in the 'V' of the engine

(M62TUB44). Not usually a problem in the UK

One final leakage area which is only found on the E38/E39 is the

thermostat housing. This leak is very difficult to find as the coolant wicks

up the thermostat heater loom and into the E-Box where it drips into the

main ECU. Often, the first sign that something wrong is an instrument

cluster warning saying the engine is running into 'Engine Failsafe' mode. A

few days later this will stop the engine running altogether.

A failed seal on the heater connection allows coolant to leak into the ECU

leading to Engine Failsafe mode

Overheating

If your temperature gauge starts heading for the red zone - stop

immediately - and if you can't stop, put the heater on the highest

temperature and the fan on full speed to pull heat from the engine. This

can also help diagnose the problem, if you get no heat from the heater

then no coolant is circulating. If running the heater at full reduces the

coolant temperature (as seen on the gauge), then a lack of cooling

efficiency is more likely. As long as the car is not driven any further with

the gauge in the red then normally no engine damage will occur. But drive

a couple of miles and severe engine damage will be seen with failure of

the head gaskets being the start of a lot of bad news.

This is a big subject on the V8's, read any E38 Forum and there are

endless posts describing temperature gauges that inexplicably head

towards the red zone. There are two main reasons for the problem, not

enough air-flow and failure to move coolant around the system - each

problem has its own symptoms. Finding the cause of overheating can be

difficult, but there are usually some clues. If the car overheats after work

has been done on the cooling system, or it was drained during other work,

then the cause is often air trapped in the system which stops the coolant

circulating. Where overheating happens gradually, especially on very hot

days, then a lack of efficiency (due to sediment in the radiator, damaged

radiator fins etc) is usually the cause.

Certain cooling problems fail in unique ways making diagnosing the fault

easier, these are all explained below. It is worth saying at this point that it

is essential that there are no leaks in the system (see previous section),

leaks not only lose coolant, but when the engine cools they introduce air

into the system - and often into areas that can stop the coolant

circulating. The water pump is a centrifugal type and it will fail to operate

if air is introduced.

Overheating at idle and slow speed

Overheating at slow speed and idle is usually due to the lack of airflow

through the radiator (but not always). At idle and slow speed the airflow

through the main radiator is not sufficient to remove the heat from the

coolant. To increase the airflow there is a viscous-coupled fan attached to

the water pump.

The viscous-coupled fan on a 740i fitted with the M62TUB44, the radiator

shroud has been removed for clarity

The fan is attached to the water pump and driven by the serpentine belt

from the crankshaft pulley. The finned part in the centre of the fan is a

viscous coupling. This allows the fan to freewheel when not required, and

then lock when additional airflow is needed for cooling. What is not fully

understood is that the locking mechanism is controlled by the radiator

temperature and not the engine temperature. For the fan to operate

correctly the coolant must flow through the radiator, if the coolant is not

circulating (due to an air lock or a failed thermostat) then the fan will

refuse to move air at any volume.

When working correctly, the fan will idle when the radiator temperature is

below 95C (+/- 4C) and can be stopped from rotating with a rolled-up

newspaper. Once above this temperature, the viscous coupling will lock

and move great volumes of air through the radiator - this is quite

noticeable as the noise level increases and the airflow can be felt across

the engine. It is worth noting that the viscous coupling also locks up when

the engine is started from cold for 30 seconds or so. As already

mentioned, the air-conditioning system has its own cooling fan in front of

the radiator, this is called the auxiliary fan. E31's, pre-facelift E38's and

E39's have a two speed fan, normal speed is used by the air-conditioning,

high speed is commanded by the DME (engine computer) when the

radiator outlet temperature exceeds 99C.

The auxiliary fan on an 840ci Sport - used for both the A/C and saves the

day when overheating

At slow road speed or at idle, if the temperature gauge is seen to leave

the centre position and head to the red, and then return to the centre in

regular cycles - this often indicates failure of the viscous coupled fan. The

reason for this is that the viscous coupled fan is not providing sufficient

airflow through the radiator, the coolant temperature increases and the

temperature gauge starts climbing. At a radiator outlet temperature of

99C the auxiliary fan cuts in at high speed, reduces the coolant

temperature and the temperature gauge returns to the centre.

If the auxiliary fan has also failed (often not noticeable except the air

conditioning is weak), the temperature will keep rising until the coolant

system fails. The above is only true if the failure is at slow speed or idle.

At higher speeds (>30 MPH), the forward motion is enough to provide

enough airflow through the radiators.

Overheating at any road speed

Overheating when driving at a good speed is usually due to poor

circulation of coolant rather than a lack of airflow through the radiator.

Poor circulation can be due to a number of factors, a failed thermostat, a

failed water pump (unusual, but has happened), a blockage or a shortage

of coolant.

Bleeding

If you have just replaced a part of the cooling system and had to refill,

then the possibility is that there is air still in the system. Some cars prove

really difficult to bleed, but this is usually due to a coolant leak. Some

coolant leaks go unnoticed as they leave no trace, but if coolant is getting

out, air is getting in. Air in the cooling system can stop the water pump

operating correctly as the air can sit between the pump and the

thermostat. It is important, when replacing the thermostat, to get the

bleed hole at the top - this allows air to pass through the system rather

than getting stuck:

The bleed hole on the thermostat shown above is at the front - always

place the thermostat so this is uppermost.

There are many different methods to bleed the V8 cooling system, but on

all the V8's I have owned and worked on, the methods shown here and

here have never failed. The system on the E38/M62 operates above

boiling point (105 C), so bleeding with the expansion tank cap removed

will only expel coolant once the engine reaches running temperature.

Bleeding with the cap removed will introduce more air into the system.

Head gasket failure?

Failure of the head gasket(s) on the M60/M62/M62TU is very rare if the

engine has never over-heated, but many heads have been removed only

to find the gaskets intact and the block and head in good condition. This

usually happens when the engine keeps refusing to bleed correctly and

the temperature rises past the centre each time. As previously discussed,

this can be due to a coolant leak that is not discovered. Before

contemplating removing the heads, replace the coolant (as this may be

contaminated) and use a block tester (shown below) to check for any

exhaust gasses in the coolant:

A block tester is essential for finding failed head gaskets. The fluid

changes colour if exhaust gasses are detected.

Blockages

As already discussed, the most common blockage is air which often gets

trapped between the thermostat and water pump. If the coolant is not

circulating the radiator will stay cool and the bottom radiator hose will

remain just warm. As the radiator outlet temperature is low, neither the

viscous-coupled fan or the auxiliary fan will run and the engine will rapidly

overheat.

The obvious place to start when the coolant is not circulating is the

thermostat. Thermostats can fail closed, and this will stop the coolant

circulating through the main radiator. However, a failed thermostat will not

stop the coolant circulating the heater matrix - if you have heat in the

cabin but no circulation through the radiator then the thermostat is likely

to have failed closed. If you have no heat in the cabin and no circulation

through the radiator, then there is either an air-lock at the water pump, a

mechanical failure of the water pump or a blockage.

Failure of the water pump to circulate the coolant is very rare, however,

there was a period where the water pump vanes were made of plastic and

these could disintegrate. If the water pump is replaced, check that the

vanes have not disappeared, if they have then a comprehensive flushing

will be required to get the pieces out of the system. Make sure the

replacement has a metal impeller as shown below:

A failed BMW water pump - the plastic impellers can fail and block the

coolant system.

Where the water pump and thermostat has been replaced and the coolant

still fails to circulate then the main radiator needs to be checked by

flushing. Older radiators can become blocked with rust where incorrect

coolant has been used (or just plain water is in the system). If the

radiator is much hotter at the top in comparison to the bottom then it is

quite likely the radiator is partially blocked. Where is radiator is found to

be partially blocked this usually means the radiator has reached the end of

its life. Although the radiator can be flushed, the blockage is usually

oxides that have been produced by decomposition of the internal structure

and after flushing the radiator may leak or burst. The best course of

action is to remove the radiator and fully flush the system before

replacement.

Don't forget the temperature sensor

Where the temperature gauge moves extremely rapidly in the first few

minutes of running, the fault is often due to a faulty temperature sensor

or the wiring to it. On facelift (post 10/98) E38's and E39's, the

temperature sensor wiring shares the same loom as the heater wires for

the mapped thermostat. It is well known that the connector on the heater

can fail and leak coolant - this not only wicks up the loom to cause

problems with the ECU, but also can degrade the temperature gauge

wiring giving false readings. The temperature sensor itself can also fail in

a way to provide erratic temperature readings. Where the movement of

the gauge makes no sense and there are no other signs of overheating

suspect the sensor.

Conclusion on cooling system

The cooling system on the V8's can certainly cause problems - some are

simple as when something explodes and can be replaced. Other problems,

as discussed above, can cause misery, especially when bleeding fails to

solve intermittent overheating. These problems are very often due to

small leaks that are not noticed - if you are needing to 'top-up' the coolant

regularly you have a leak. You will not cure overheating problems

until the leak is found and rectified. The reason for this is that the

cooling system runs at internal temperatures that are above the boiling

point of the coolant, even on engines fitted with an 85C thermostat. If you

have a small leak, the system will not pressurise to the required 2 Bar. In

this situation the coolant will boil at the cylinder walls and produce gasses

that stop the water pump operating correctly, and this will allow the

engine to overheat - especially when the thermostat is fitted with the

bleed-hole at the bottom rather than at the top.

Before worrying about failed head gaskets, it is much more likely that

there is something wrong with the cooling system. It is very unusual for

the V8 head gaskets to fail - it is usual for the system to acquire small

leaks, for the viscous-coupled fan to fail, to have air trapped in places

from which it is difficult to remove and the temperature sensor to lie -

don't panic, it's usually something simple!

SEARCH MEEKNET