Timm’s BMW E63 and E64 Ignition Coil and Sparkplug Replacement

N62 Engine on the 645i and 650i

Break out the toolbox - you are going to need a few for this one

I’ve done plugs and coils on loads of BMW V8’s with the M60/M62M62TUB engines - but the N62/N62TUB has proven to be the most awkward,

I’ll never complain when I change the E31 plugs again. The main problem is that there is little room to get the coils out from the deep wells,

they hit all sorts of things, and these things need to be moved out of the way or removed entirely.

If this is the first time you have replaced plugs, then use a torque-wrench to make sure you have tightened the plugs correctly (set to 25

Newton-Metre). The new plugs have washer that needs to be compressed and this may feel as though the plug is tight enough as it begins to

get crushed. But, when the plug starts to feel tight, it is usually another 180 degrees before the washer is fully compressed. If the washer is

only partially compressed, the plug will slowly work loose and then come out with a loud pop, taking the threads with it - and the head will

then need to be Helicoiled before it can be used again.

Right, let’s get on with it, to start with you need to get the engine covers off, the air filter housing off and a bunch of other stuff that is

covered later. The top cover is held with 4 x 10mm conical nuts, the side covers secured by bosses pushed into rubber grommets

For Bank 2 (passenger side in the UK) the air filter housing needs to be removed to give access to the coils. Disconnect the MAF sensor by un-

clipping the cover and then pulling the connector off. Loosen the large Jubilee clip and unclip all the fixings around the air-filter cover. The air-

filter cover can then be removed from the air intake hose by twisting the complete assembly

The lower half of the air-filter housing is held by three wide-head Torx bolts - the filter housing can then be pulled backwards and be

disconnected from the cold air inlet at the front of the car

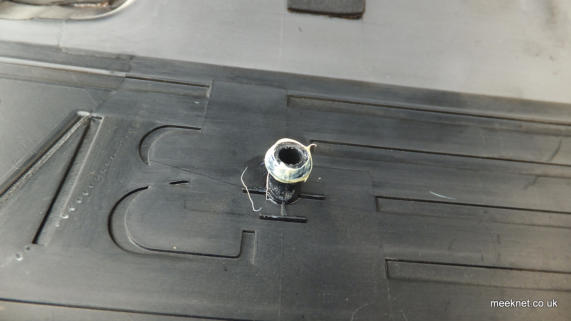

We are going to start with an easy one - good practice for the back ones. The sparkplug wells are deep and you will need a decent sparkplug

socket with a rubber insert to retrieve the plug. For the easy ones I’m using a 6” extension and a universal joint plus the sparkplug socket to

get the first plug out. First, there is a small clamp that hold down a pair of coils which needs to be removed as shown below, the fixing is a

male Torx - be careful when replacing as it is a plastic threaded hole:

Unclip the MAF connector housing

Unplug the MAF connector

Remove 4 x 10mm conical nuts

Unclip cylinder head covers

Twist air filter cover to release from air intake

Remove three Torx bolts

Pull air filter housing from cold-air inlet

With the clamp removed you have access to the ignition coil’s connector - the connector is held in place with a plastic clamp, lever the

connector upwards as shown below, it will click and then allow you to pull the clip vertical which will separate the connector from the coil

The coil needs a good pull to release it from the plug - it is easier to carefully lever the coil as shown below - and the coil is out

Next, the plug is removed, I’m using a 16mm plug socket, a 6” extension and a standard ratchet - the front plug is easy to remove without

the universal joint. I’m fitting the recommended plug, NGK Laser Iridium IZFR6H11. These are pre-gapped and don’t need adjusting. The

plugs have an exposed electrode (unlike twin electrode plugs), so be careful inserting the plug into the bore to ensure the electrode is not

knocked - as this will close the spark-gap.

When I fit a new plug I always put a small dab of LM grease on the very first thread - it makes it a bit easier when fitting the plug. Remove

the ratchet from the 6” extension, fit the plug into the sparkplug socket and carefully insert the plug into the well. The plug will centre itself

and you will find it is easy to twiddle the extension until the plug bottoms-out on the crush-washer.

You can now fit the torque-wrench to the extension and tighten to 25 Newton-Metre. As said before, you have to apply enough force to

compress the crush washer for around 180 Degrees before the torque will reach 25 Newton-Metre. Get used to the amount of torque needed

to fit the plug - it’s unlikely that you can fit it when you get to the back plugs!

Once the plug is torqued into position you can fit the new coil - this is pretty straight-forward, just align it as shown below and then give it a

good push to get it properly seated - it needs quite a shove due to the new rubber. To refit the connector, push the plug into the socket and

push down on the connector clamp. The plug will be drawn into the socket and held firmly.

Right, that’s the easy one done. The next one back, cylinder 6 is just as easy. Once you have fitted the coils and plugs in cylinder 5 and 6,

refit the plastic clamp - when it is fully tightened push down on each side of the clamp to ensure the coil is fully inserted.

Well, that was the easy pair to do, it gets a bit harder now, you will need a ratchet to remove the coil clamp this time. For cylinder 7 you

will need the universal joint as shown below

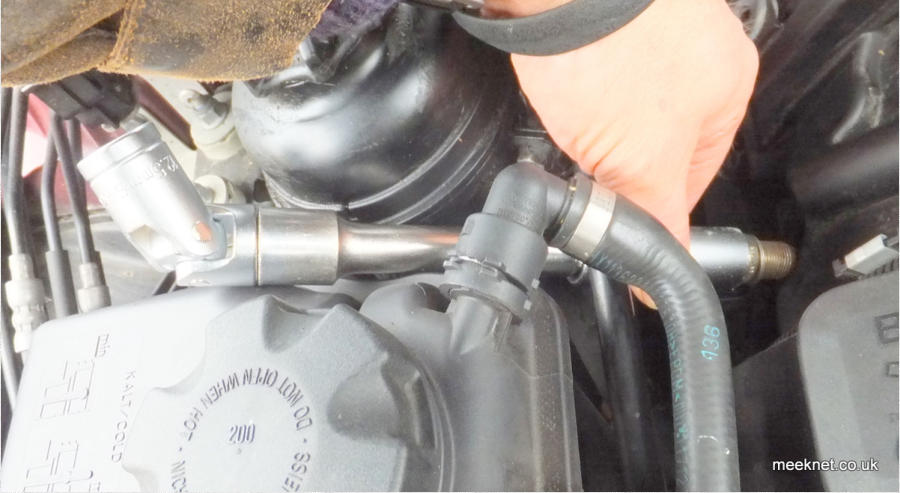

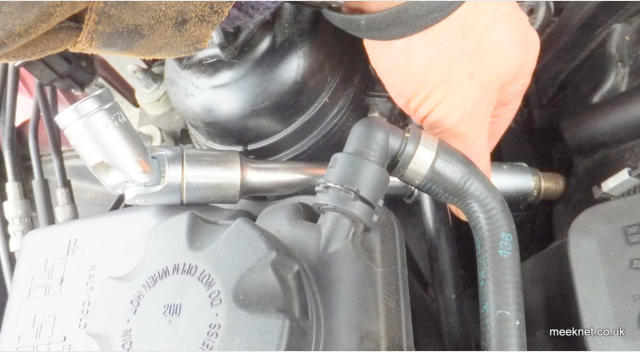

For cylinder 8 you will need a bit more hardware. You also need to remove the plastic cover that protects the battery positive cable - this

is held on with a single plastic nut - the other end of the cover fits into a hole in the metalwork. The pipe shown below is the petrol feed

to the injector rail. At some point when removing the coil this needs to be pulled out of the clamp and moved aside.

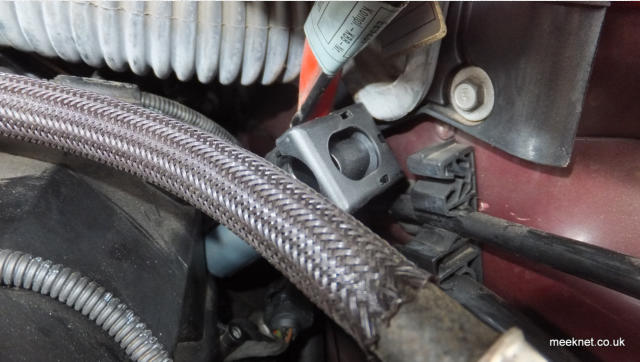

The combination of tools I needed for cylinder 8 are shown below - sparkplug socket, 1/2” universal joint, 1/2” to 3/8” converter, 3/8”

universal joint and a ratchet with a handle slim enough to fit a length of pipe:

At this point it really just a case of struggling to get the coil out past the obstructions. Here’s the coil coming out:

My combination of universal joints and converters has a lot of backlash, so it took a while to get the plug out due to only managing a single

click on the ratchet each go - but it came out in the end:

Well, it looks easy in the pictures, but it isn’t - there is not really enough room to get the coil in and out, at one point the coil got well and

truly stuck and wouldn’t go in or come back out - and then it just popped in as if by magic. Fortunately, cylinder 8 is the hardest of all

eight. The other side, cylinders 1 to 4 are awkward, but a lot easier.

You still need a universal joint but you can use the torque wrench on most of the cylinders. Cylinders 1 and 2 come out reasonably easy

but the coil has to be threaded through the expansion tank and CHF reservoir.

Cylinder 2 and 4 are much the same, awkward but not impossible without removing anything. Cylinder 3 has a problem here:

That’s the air-conditioning low-pressure servicing valve assembly - it’s bolted to the inner wing - I have removed the two nuts with captive

washers ready to move it. With the nuts removed the bracket can be moved inwards away from the studs and then pushed downwards so

the coil can get past, This means bending the refrigeration pipework which is a bit scary to say the least. It’s still a bit of a fiddle to get

the coil out but it will come out without much hassle.

At least on bank 1 the torque wrench fits (just about) on the first two cylinders - but that’s just about it. When refitting the side covers

wipe a bit of grease on the bosses - it makes it a lot easier to fit. And don’t forget to refit the clamps

All done - Time for a Cup of Tea

Parts used below

Timm’s BMW E63 and E64 Ignition

Coil and Sparkplug Replacement

N62 Engine on the 645i and 650i

Break out the toolbox - you are going to need a

few for this one

I’ve done plugs and coils on loads of BMW V8’s with the M60/M62M62TUB

engines - but the N62/N62TUB has proven to be the most awkward, I’ll

never complain when I change the E31 plugs again. The main problem is

that there is little room to get the coils out from the deep wells, they hit all

sorts of things, and these things need to be moved out of the way or

removed entirely.

If this is the first time you have replaced plugs, then use a torque-wrench

to make sure you have tightened the plugs correctly (set to 25 Newton-

Metre). The new plugs have washer that needs to be compressed and this

may feel as though the plug is tight enough as it begins to get crushed.

But, when the plug starts to feel tight, it is usually another 180 degrees

before the washer is fully compressed. If the washer is only partially

compressed, the plug will slowly work loose and then come out with a loud

pop, taking the threads with it - and the head will then need to be

Helicoiled before it can be used again.

Right, let’s get on with it, to start with you need to get the engine covers

off, the air filter housing off and a bunch of other stuff that is covered later.

The top cover is held with 4 x 10mm conical nuts, the side covers secured

by bosses pushed into rubber grommets

For Bank 2 (passenger side in the UK) the air filter housing needs to be

removed to give access to the coils. Disconnect the MAF sensor by un-

clipping the cover and then pulling the connector off. Loosen the large

Jubilee clip and unclip all the fixings around the air-filter cover. The air-

filter cover can then be removed from the air intake hose by twisting the

complete assembly

The lower half of the air-filter housing is held by three wide-head Torx

bolts - the filter housing can then be pulled backwards and be

disconnected from the cold air inlet at the front of the car

We are going to start with an easy one - good practice for the back ones.

The sparkplug wells are deep and you will need a decent sparkplug socket

with a rubber insert to retrieve the plug. For the easy ones I’m using a 6”

extension and a universal joint plus the sparkplug socket to get the first

plug out. First, there is a small clamp that hold down a pair of coils which

needs to be removed as shown below, the fixing is a male Torx - be careful

when replacing as it is a plastic threaded hole:

Unclip the MAF connector housing

Unplug the MAF connector

Remove 4 x 10mm conical nuts

Unclip cylinder head covers

Twist air filter cover to release from air intake

Remove three Torx bolts

Pull air filter housing from cold-air inlet

With the clamp removed you have access to the ignition coil’s connector

- the connector is held in place with a plastic clamp, lever the connector

upwards as shown below, it will click and then allow you to pull the clip

vertical which will separate the connector from the coil

The coil needs a good pull to release it from the plug - it is easier to

carefully lever the coil as shown below - and the coil is out

Next, the plug is removed, I’m using a 16mm plug socket, a 6” extension

and a standard ratchet - the front plug is easy to remove without the

universal joint. I’m fitting the recommended plug, NGK Laser Iridium

IZFR6H11. These are pre-gapped and don’t need adjusting. The plugs

have an exposed electrode (unlike twin electrode plugs), so be careful

inserting the plug into the bore to ensure the electrode is not knocked -

as this will close the spark-gap.

When I fit a new plug I always put a small dab of LM grease on the very

first thread - it makes it a bit easier when fitting the plug. Remove the

ratchet from the 6” extension, fit the plug into the sparkplug socket and

carefully insert the plug into the well. The plug will centre itself and you

will find it is easy to twiddle the extension until the plug bottoms-out on

the crush-washer.

You can now fit the torque-wrench to the extension and tighten to 25

Newton-Metre. As said before, you have to apply enough force to

compress the crush washer for around 180 Degrees before the torque

will reach 25 Newton-Metre. Get used to the amount of torque needed to

fit the plug - it’s unlikely that you can fit it when you get to the back

plugs!

Once the plug is torqued into position you can fit the new coil - this is

pretty straight-forward, just align it as shown below and then give it a

good push to get it properly seated - it needs quite a shove due to the

new rubber. To refit the connector, push the plug into the socket and

push down on the connector clamp. The plug will be drawn into the

socket and held firmly.

Right, that’s the easy one done. The next one back, cylinder 6 is just as

easy. Once you have fitted the coils and plugs in cylinder 5 and 6, refit

the plastic clamp - when it is fully tightened push down on each side of

the clamp to ensure the coil is fully inserted.

Well, that was the easy pair to do, it gets a bit harder now, you will

need a ratchet to remove the coil clamp this time. For cylinder 7 you will

need the universal joint as shown below

For cylinder 8 you will need a bit more hardware. You also need to

remove the plastic cover that protects the battery positive cable - this is

held on with a single plastic nut - the other end of the cover fits into a

hole in the metalwork. The pipe shown below is the petrol feed to the

injector rail. At some point when removing the coil this needs to be

pulled out of the clamp and moved aside.

The combination of tools I needed for cylinder 8 are shown below -

sparkplug socket, 1/2” universal joint, 1/2” to 3/8” converter, 3/8”

universal joint and a ratchet with a handle slim enough to fit a length of

pipe:

At this point it really just a case of struggling to get the coil out past

the obstructions. Here’s the coil coming out:

My combination of universal joints and converters has a lot of backlash,

so it took a while to get the plug out due to only managing a single click

on the ratchet each go - but it came out in the end:

Well, it looks easy in the pictures, but it isn’t - there is not really enough

room to get the coil in and out, at one point the coil got well and truly

stuck and wouldn’t go in or come back out - and then it just popped in as

if by magic. Fortunately, cylinder 8 is the hardest of all eight. The other

side, cylinders 1 to 4 are awkward, but a lot easier.

You still need a universal joint but you can use the torque wrench on

most of the cylinders. Cylinders 1 and 2 come out reasonably easy but

the coil has to be threaded through the expansion tank and CHF

reservoir.

Cylinder 2 and 4 are much the same, awkward but not impossible without

removing anything. Cylinder 3 has a problem here:

That’s the air-conditioning low-pressure servicing valve assembly - it’s

bolted to the inner wing - I have removed the two nuts with captive

washers ready to move it. With the nuts removed the bracket can be

moved inwards away from the studs and then pushed downwards so the

coil can get past, This means bending the refrigeration pipework which is

a bit scary to say the least. It’s still a bit of a fiddle to get the coil out but

it will come out without much hassle.

At least on bank 1 the torque wrench fits (just about) on the first two

cylinders - but that’s just about it. When refitting the side covers wipe a

bit of grease on the bosses - it makes it a lot easier to fit. And don’t forget

to refit the clamps

All done - Time for a Cup of Tea

Parts used below