Timm's BMW E31 8-Series Common Problems

I’ve no idea why it has taken so long to write a ‘common problems’ for the 8-Series, possibly because I hadn’t suffered enough yet. I got

my first E31 in early 2009, a 1997 840ci, and my second, a 1999 840ci two years later - the amount of repairs detailed on the E31 section

of meeknet is testament to the fact that these cars do go wrong quite a bit - but also indicates that, with help from my mate Bob (often

seen in the routines holding or hitting something) and the expert help of Lee Shannon we managed to keep them both running, and running

rather well on an extremely limited budget.

Calling the E31 unreliable is a bit unfair, mine have only fizzled out to extent that they can’t get us home on two occasions. Once when a

water pump bearing allowed the viscous-coupled fan to eat the radiator, and once when the famous ‘exploding coolant hose’ rightfully lived

up to its name - and even then I borrowed the AA mechanics tools and managed to bypass the failed hose. No, it is the bits and bobs that

go wrong, lights, wiring, worn-out bushes, cosmetic issues - the worst of which are detailed here.

So, in order of the most likely, here are the common problems - this list is mainly for the V8. The V12 has its own specific problems

which usually involves the Electronic Motor Load (EML) control of the engine. These days it is better know as a fly-by-wire control system -

and it was extremely reliable in 1988 when first introduced on the BMW E32 750i - and still going strong in 1991 when the same system

was used in the E31 850i. Nearly 30 years later the EML system (as would be expected) is getting a bit unreliable due to ageing of the

electronic throttle bodies (DK’s), the strange cylinder identification sensors which take the place of camshaft sensors and the complication of

having two of everything that have to work in concert.

The good news on the V12 engines is that, apart from damage caused by a lack of cylinder head lubrication, the mechanical parts are nearly

bulletproof - and the EML system just needs a bit of common sense to fault-find - the system even has its own built-in diagnostics which

can be enabled with presses of the throttle pedal.

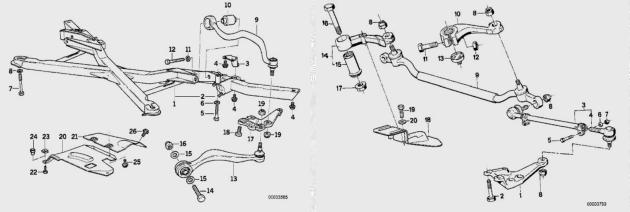

1. The Dreaded Shimmy

All the big BMW’s can suffer from the dreaded 'shimmy'. This is wheel-wobble that usually first shows itself under braking, for instance, when

coming off a motorway intersection and braking from high speed. The wobble can be felt through the steering-wheel but it usually disappears

as the car speed reduces. Sometimes this is all you ever get, but more usually you will start to get wobble as the car is accelerated through

50 - 60MPH. The more you drive the car the worse it will get. The wobble is quite often accompanied by tram lining and a general feeling of

imprecision from the steering in general.

The shimmies are often an indication of general wear in the steering system and suspension, the BMW E31 has a great deal of weight over

the front wheels, especially when braking. It also seems to have a resonant frequency that occurs between 50 and 60 MPH, if there is any

weakness it is at this speed where the problems will occur. The shimmies can be repaired, often very simply. Click here for repair information

2. Cooling system

This is another problem that the E31 shares with the E32 and E38. There are two areas of the cooling system that are particularly weak:

Radiator. The E31 radiators have a plastic body, they break around the Top Hose connection. The Top Hose fitted to the radiator with the aid

of a Jubilee-clip. The usual problem is that the plastic pipe that the hose is connected to cracks under the Jubilee-clip and this causes a small

weep around the hose that is difficult to trace. The usual evidence is white marks down the side of the radiator. The only repair is the

replacement of the radiator.

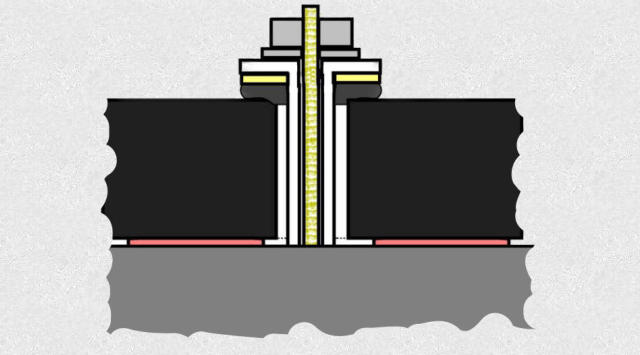

Viscous Fan. The Viscous Fan is mounted on the water pump shaft and is driven by the main belt from the crankshaft pulley. The assembly

consists of a temperature-dependant viscous-clutch driven from the pump shaft that drives a large plastic fan. When the clutch is cold the fan

idles and can be stopped with a rolled-up newspaper (the usual test), once the clutch is hot the fan is driven with a much greater torque and

produces a great deal of air-flow.

The usual problem is that the clutch fails and the fan cannot produce enough air-flow. The fault will show itself when the car is stationary

when it will rapidly overheat. The temperature-rise is usually halted by the the auxiliary fan (A/C fan) which will operate independently to the

A/C system when required. Once the car is moving the temperature starts to drop. A more unusual problem is that the clutch seizes, this is

first noticed by large whooshing noises when the car is revved-up. Replace the viscous coupling immediately if this happens as the fan will

disintegrate and this can cause all sorts of damage including big holes in the bonnet! Replacement of the Viscous Fan is pretty simple and is

covered here (E38 shown E31 similar)

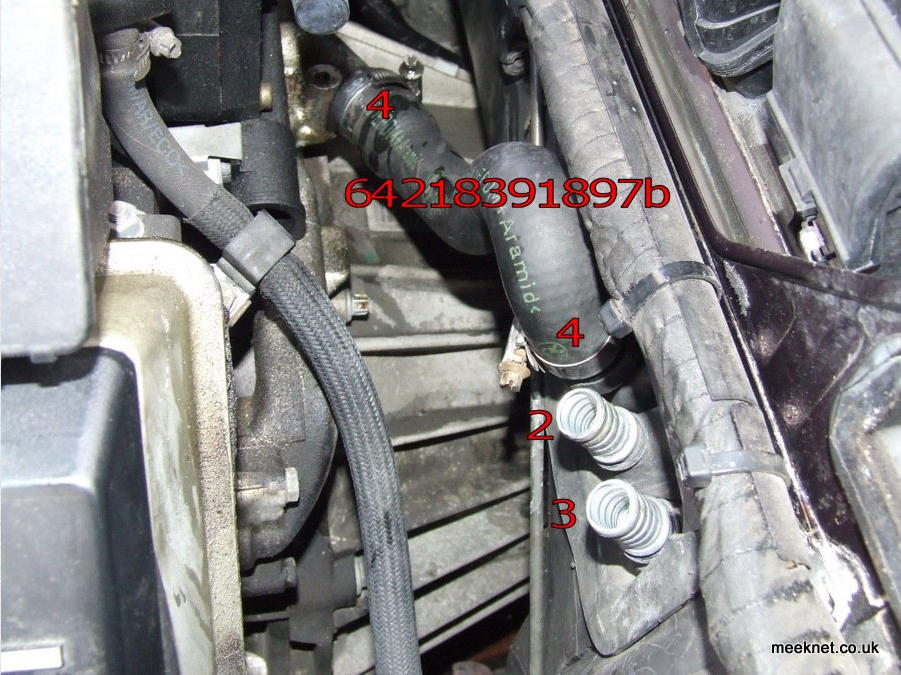

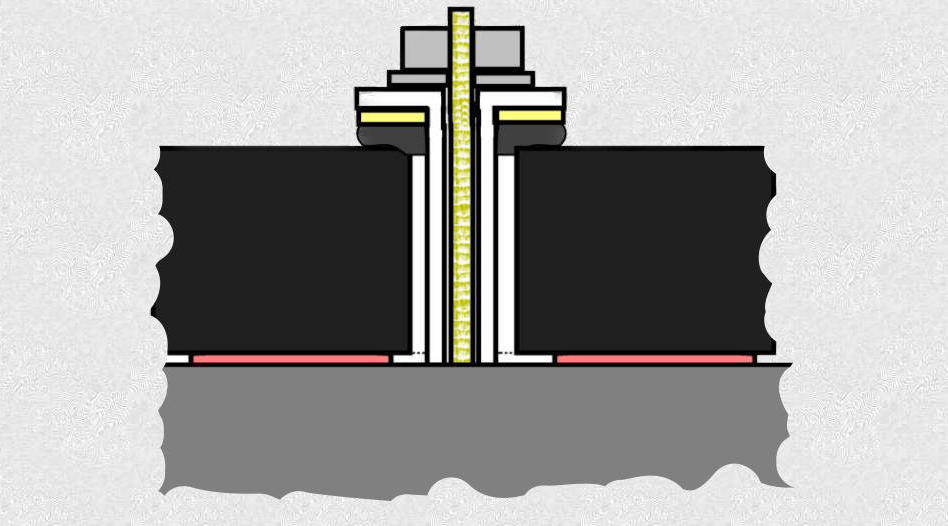

The famous exploding hose. Well, there are two of them - one from the engine to the cabin heater matrix, the other from the engine to the

auxiliary water pump - the common bit being that one end wobbles around with the engine, the other end stays still. The hose gets a lot of

physical action and eventually pops - either that or (as happened to me) the pipe snaps the union at the auxiliary water pump. Neither is

much fun - but at least on the E31 you can get to the blighters by removing the mircrofilter housing, all covered here.

3. Lumpy Idle caused by vacuum leaks

Although the V12 can have leaking inlet manifold gaskets, this really is the domain of the V8 - they leak all over the place. PCV valve,

throttle-body gasket, failing rubber bungs and the manifold gaskets themselves. Although the first signs are an uneven idle, these problems

can end up with damaged catalytic converters because of a strange anomaly of the DME 5.2 software on the M62 and DME 3.3 on the M60

engine. The DME adjusts the fuel/air ratio to combat the lean mixture and reaches the extreme limits of the additive adaptations - and then

the DME adjusts the multiplicative adaptations until the correct fuel/air ratio is reached at idle.

That might not seem a problem - except the multiplicative adaptations also affect the fuel/air ratio at higher revs and engine loads - pushing

the mixture into the rich range - and it is that which damages the catalytic converters as well as returning awful MPG. The hard bit was

always replacing the lower manifold gaskets - I hated that job as it involved bending the fragile and brittle engine wiring looms at right-

angles - and that is not a good idea on a 20 year-old loom. But, a year or so ago I came up with a better plan - all explained here

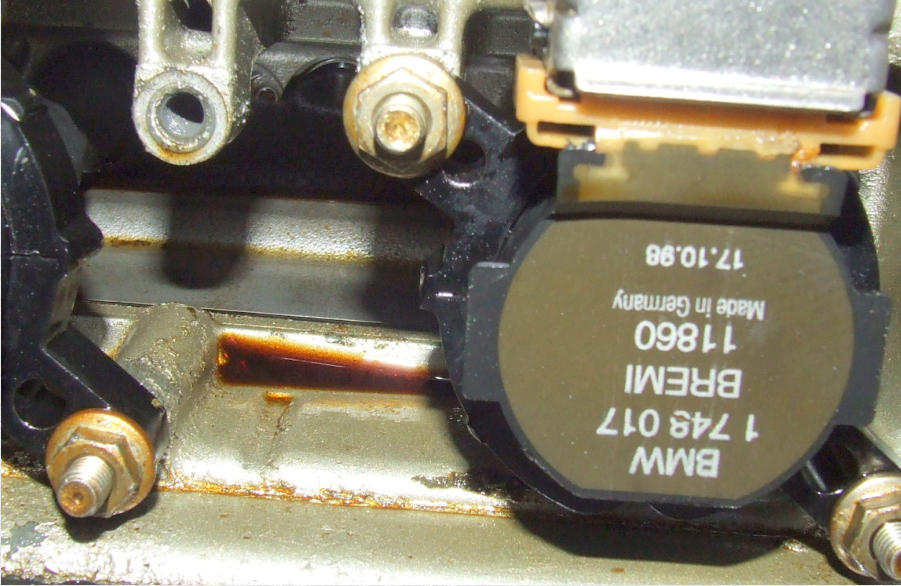

4. Rocker-Cover Oil Leaks.

A small oil leak isn't too much of a problem unless the oil fills up the spark-plug holes. Unfortunately this is exactly what happens on the

V8 models. The coil-over-plug ignition coils have short HT-stubs, and it is these stubs that are damaged by the oil. Once the HT-stubs are

damaged the engine will start to misfire. The repair is covered here (E32 shown but E31 similar).

5. Noisy Tappets.

There are two different problems here. The M60/M62 V8-engined cars get noisy tappets that come and go, this is not usually a serious

problem and is covered here.

The M70 V12-engined cars get noisy tappets due to a lack of lubrication - and that can be serious. The lack of lubrication is due to the

loosening of hollow bolts known as 'Banjo Bolts'. These bolts direct oil from the upper oil gallery to the cam spray bar. The problem is that

the bolts cannot be tightened too much as they will be damaged due to the hollow construction and they eventually come loose and this

starves the front lobes of oil. The bolts should be locked with thread-lock but even this gives up, especially when the bolts are 'checked for

tightness'. The lack of lubrication has serious consequences - apart from the obvious cam wear, the rockers can seize - and snap in half -

and that means a long repair involving removing the cylinder heads to get the camshaft out. The same method of cam lubrication was used

on the M30 engine - and many E32’s were scrapped due to snapped rockers.

Banjo Bolts can be purchased with wire-holes so the bolts can be wired in position, this is the preferred method as it is impossible to

remove all traces of the oil from the gallery which is required to use thread-lock. Unfortunately, once the tappets get noisy the cam is

starting to wear quickly, and if left too long the rocker will seize and then snap in half, the wise money is on replacing the Banjo Bolts with

the wired types before this becomes a problem.

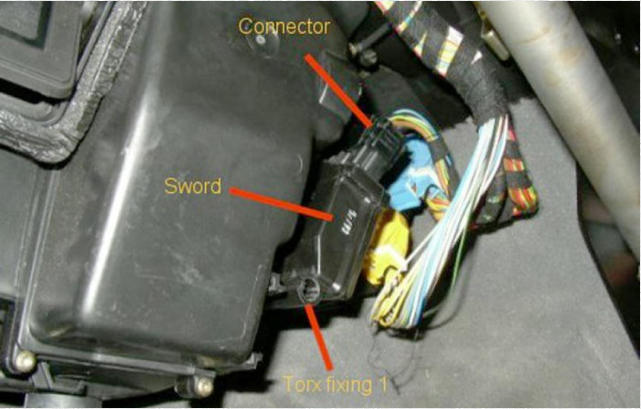

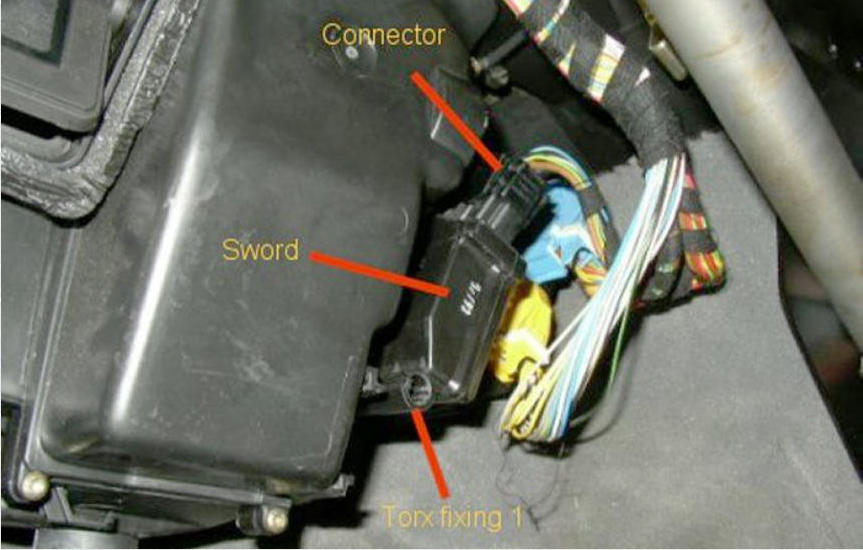

6 Blower Final Stage (Sword) Failure.

Another classic problem that causes much angst. The 'Sword' is used to control the speed of the ventilation system blower fan. Rather than

just having a couple of ballast resistors as was seen in lesser models, the E31 has a continuously-adjustable speed control. This is achieved

with a number of Field-Effect-Transistors (FET's) mounted on a metal heatsink that vaguely resembles a sword. The Sword is mounted in

the blower's air-flow just in front of the Evaporator.

When the FET's fail they usually fail short-circuit which means that the fan runs continuously at full-speed. If the solder-joints fail the fan

fails to run unless the fan-speed is set to full, this is because a relay is used across the FET's at full-speed. Failure of the sword is usually

due to a blocked Microfilter, the driver increases the fan-speed to compensate but the airflow across the FET's is insufficient to cool them.

They get hot enough to melt the solder connections which eventually leads to 'dry' joints, quite often the FET's give up altogether. The FET's

can be replaced with a little soldering skill. Removal of the Sword is not too bad on LHD models - on RHD models it’s a lot harder.

7. Trans Prog Error.

If there is one fault that makes you sweat, this is it! You get the message of doom on the OBC and the gearbox locks itself in 3rd on the 4-

speed boxes or 4th on the 5-speed boxes. You immediately realise that the cost of a replacement box is more than the car is worth and aim

the car at something that will produce a terminal insurance claim. However, don't panic, in 9 cases out of 10 the problem is easy to fix. Here

is the most likely candidates:

Battery Voltage Too Low. The E31 hates having a low battery voltage and one of the first things that gives up is the gearbox. Although

the EGS (control unit) keeps running, the 12V solenoids in the gearbox don't, the EGS sees this as a failure of the valve-body and gives up.

Low battery voltage is often due to short trips, failing batteries or a faulty alternator. Replace if needed or give it an overnight charge and

have another go, hopefully the problem will not return.

S.E.M Switch. This is the Sports, Economy, Manual switch next to the shifter (marked SE* on the V8's). Although it is a simple momentary

switch it can intermittently make contact when in the rest position, or select 'S' and 'M' at the same time. This causes an error in the EGS.

The switch can be removed and cleaned or (for emergency use) you can replace it with the sunroof switch!

Shifter Selector Switch. The selector switch is a multi-pole, multi-throw unit and produces a switch pattern (akin to binary) to the EGS.

Problems occur when the contacts get dirty and the one of the switch elements fails to make contact. The switch pattern sent to the EGS is

incorrect and the EGS flags a Trans Prog Error. The shifter selector switch is located under the car on the side of the gearbox and can be

removed and cleaned with contact cleaner, but not usually successfully, replacement is often the way forward.

Low ATF Level - Filter Blocked. Pretty obvious one this, however, the box usually starts slipping when cornering first. Still, when all else

has failed it is worth replacing the filter and getting the oil changed.

Shift-lock Solenoid. We’ve seen this three times now - the error code points to a failure of the shift-lock solenoid. This is an electro-

magnetic part that stops the shifter from being moved unless the brake pedal is pressed. The strange thing is that when the shifter cover is

removed to expose the solenoid - there isn’t one fitted! The problem seems to be the EGS (transmission computer) suddenly decides the

car has a shift-lock solenoid and it isn’t working. Two choices, change the EGS or fit a resistor or some other load that mimics the solenoid -

all other attempts like a long battery reset and diagnostic clearing of the error code makes no difference.

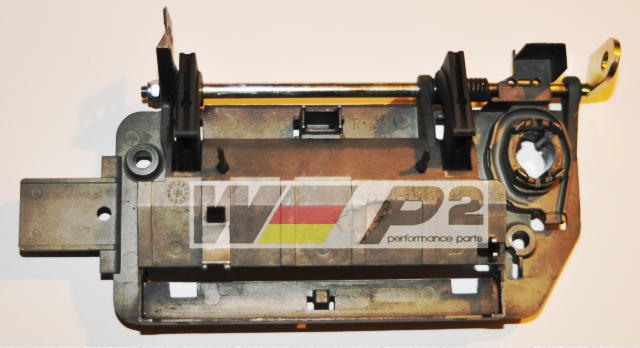

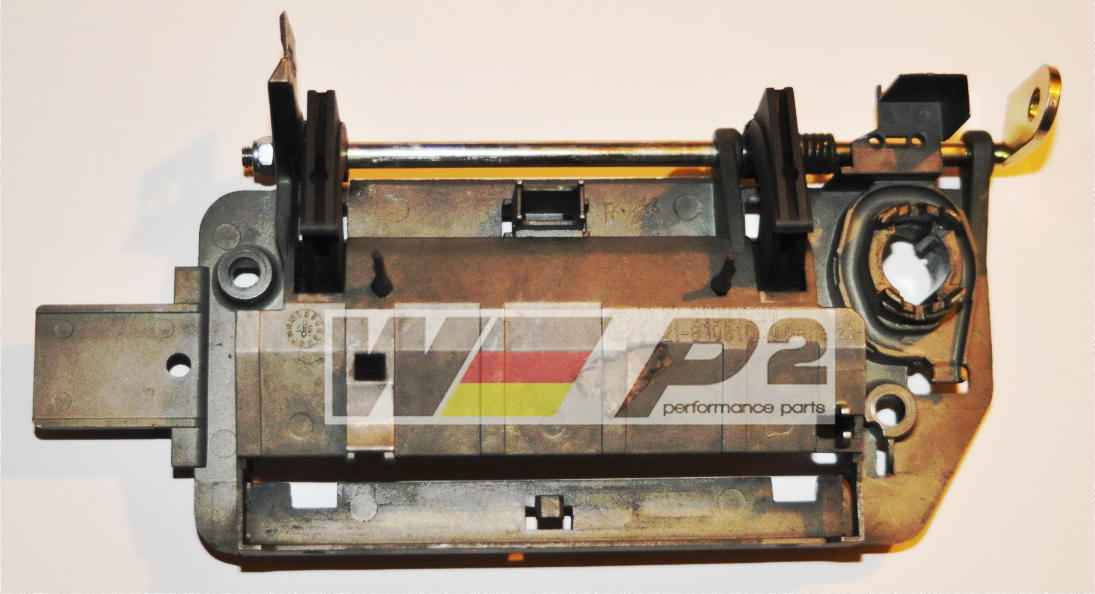

8. Door handle failure. This usually starts with the door handle having to be lifted more than usual to open the door - and then the door

will not open at all. This is due to the cheap pot-metal used for the handle construction. Doesn’t seem much of a problem until you try and

buy one from BMW - and they are NLA (No Longer Available). Fortunately they can be rebuilt using a new part which can be supplied by

Wokke (shown below) and Hyper does a similar replacement hinge. Still, a blooming nuisance all the same.

9. Boot (trunk) Hinge Wiring Loom Failure. The first you know of this problem is often confusing - an OBC warning of a Licence-Plate

Bulb Failure as you are reversing out of the drive. But, when you get out of the car and check, both of the lights are working fine. The E31

has lights not only on the rear wings but on the boot as well - the wiring to these lights are made via two looms, one on each side of the

boot. These looms eventually fail, usually starting with the larger brown wires - these are the grounds.

When a ground is lost the lower-current bulbs (such as the licence-plate lights) return current via some other higher-current bulbs - either

the brake lights or reversing lights. This is why you only get an error when in reverse - the current cannot return when the reversing lights

are on. The repair of the loom isn’t too bad, just a bit fiddly and covered here.

10. ASC+T Problems. It’s always the same, as winter rolls in, just when you needed your ABS and ASC most, both systems stop working

and your face is illuminated by warning lights on the dash. This is often caused by seizure of the charge pump on the ABS block. The

problem is that, unless you are trying to lock up the brakes on a regular basis the charge pump doesn’t have to do much at all - it gets

bored and seizes up. Sometimes all that is needed is to use diagnostics to command the pump to run for a few seconds - sometimes the

ABS block needs to be replaced.

SEARCH MEEKNET

SEARCH MEEKNET

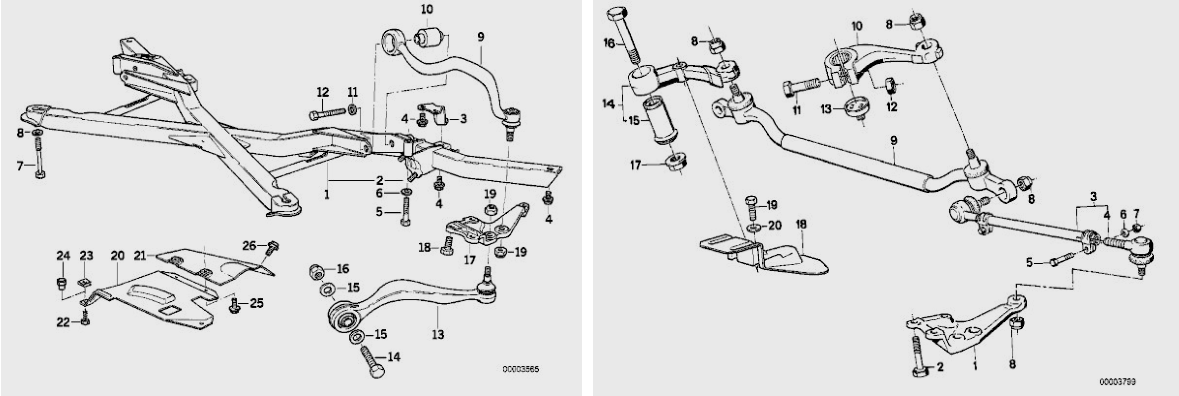

1. The Dreaded Shimmy

All the big BMW’s can suffer from the dreaded 'shimmy'. This is wheel-wobble that usually first shows itself under braking, for instance, when

coming off a motorway intersection and braking from high speed. The wobble can be felt through the steering-wheel but it usually disappears

as the car speed reduces. Sometimes this is all you ever get, but more usually you will start to get wobble as the car is accelerated through

50 - 60MPH. The more you drive the car the worse it will get. The wobble is quite often accompanied by tram lining and a general feeling of

imprecision from the steering in general.

The shimmies are often an indication of general wear in the steering system and suspension, the BMW E31 has a great deal of weight over the

front wheels, especially when braking. It also seems to have a resonant frequency that occurs between 50 and 60 MPH, if there is any

weakness it is at this speed where the problems will occur. The shimmies can be repaired, often very simply. Click here for repair information